Hello I want help to do paraphrasing for CW which I uploaded.and check it if included all requirmets which are showed in instruction. Also, make powerpoint file for presentation and poster. files whi

Seeb Sewage Treatment

Plant

Name:

Contents:

i. List of tables……………………………………………………………………..…3

ii. List of figure………………………………..……………………………………...4

1. Introduction………………………………………………………………………..5

2. Design aspect of the wastewater treatment plant………………….…..….….6

2.1. Design calculation………………………...……………………………………7

3. Operational aspect of the wastewater treatment plant………...……………11

3.1. Physical Therapy………………………………….......................................11

3.2. Tertiary/ Chemical Treatment Processes……………………………....….12

3.3. MPR Technology……………………………………………………………...13

4. Environmental significant…………………………………………………...….13

4.1. Problems that occur to the environment and the reason for the filtering process...........................................................................................................14

4.2. Ministry of environmental and climatic affairs………………..……....……14

6. Conclusion……………………………………………………………………….15

7. Reference………………………………………………………………….........16

i. List of tables:

| Sr.No | Tital of subject | Page of Number |

| 1) | Ministry of environmental and climatic affairs. | Page 14 |

ii. List of figure

| Page of Number | Title | Sr.No |

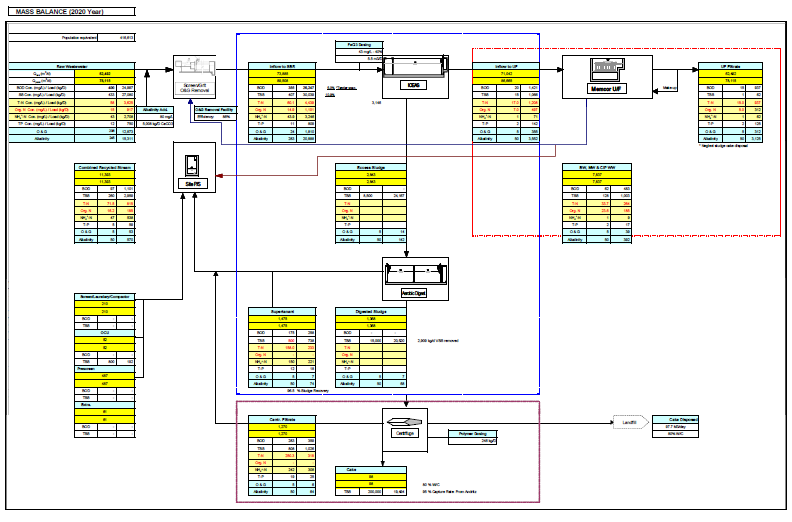

| Page 10 | Diagram of facility. | Figure 1 |

| Page 11 | Seeb STP _ MPS-1 | Figure 2 |

| Page 12 | Sludge Treatment Unit | Figure 3 |

| Page 12 | Tertiary Treatment Unit | Figure 4 |

| Page 13 | MPR | Figure 5 |

1. Introduction:

Al-Seeb station includes water treatment works, pumping stations and a wide network of pipelines. They also have a fertilizer plant in Amarat to transfer solid sewage waste as well as organic waste to a valuable commodity, which is fertilizer (both). It also supports landscaping, agriculture and recycling of sewage for irrigation. In 2014 Haya Water Company was commissioned from the State Station to provide services to all regions of Oman. Upon my visit to this station, the emergency exits were identified and how to act in case of hearing the sound of the warning and the place where it is necessary to assemble until the emergency ends. As well as not to use the elevator in the event of a fire. There are many types of emergency equipment in the site, such as fire extinguishers, fire hoses, and first-aid equipment. Also when you go to a live station, you must avoid moving machinery or places that involve the risk of falling into deep water, such as lakes or reservoirs. In addition, when you go to visit work sites, you must wear personal safety equipment represented in the helmet, safety vest and safety shoes.

The central wastewater treatment plant is the main part of the wastewater treatment process and includes several facilities designed to monitor the continuous operation of the plant:

Central Processing Units.

Water Testing Laboratory.

Chlorine Production Unit.

Treated Water Storage Basins.

Control Rooms.

Administration Offices.

The STP process consists of the main pumping station, the secondary feeder unit and the odor control unit. In the SeebSTP _ MPS 1, the wet depth is 15.5 meters from the ground floor as well as the size of the wet well 213 cubic meters and there are 6 well pumps. In addition, pump operation depends on the level.

2. Design aspect of the wastewater treatment plant:

Designing a sewage treatment plant is important whether it is successful or unsuccessful. At the operational stage it is based on design concepts. There are several points that should be considered for STEP's design:

1) Find out the real numbers that are used for the design.

For example, the real number of population and the average flow rate of an individual.

2) As a consideration for the minimum and average control and flows that come to the sewage treatment plant as effective in each unit process due to hydraulic.

3) In addition to knowing the end population at the end of the planning horizon, it should be designed to be sufficient for a long period of time.

Sewage treatment plant (STP) is the treatment of closed sewage. As the first completely closed plant in Oman capacity of 26,000 cubic meters. There are also four pumping stations of them (MPS-2, MPS-3, Al Mobellah & Al Khoud) are located outside the STP.

The main pumping station (MPS-1) transfers the collection of sewage from underground sewage pipes to the treatment plant.

The A’Seeb wastewater one task will be Muscat’s initial wastewater administration framework. Coating 189 mi2 (490 km2) for made urban environment, the system was designed for more than municipal sanitation—it Additionally supplements those region’s water assets Eventually Tom's perusing treating 100% about wastewater of the high-quality level required to gainful reuse Furthermore conveys those reused water. The water treatment plant in the state of Al-Seeb is added to the vital project, which works to treat the water flowing through the networks and the capacity of about 60 thousand cubic meters per day as a first stage and 80 thousand cubic meters as a second phase of treatment water.

The STP process consists of the main pumping station, the secondary feeder unit and the odor control unit. In the Seeb STP _ MPS 1, the wet depth is 15.5 meters from the ground floor as well as the size of the wet well 213 cubic meters and there are 6 well pumps.

2.1 Design calculation:

Data given:

BOD

minimum = 350 mg/L

maximum = 400 mg/L

Q = design flow = 119232 m3 /d

sludge age = 10 d

Y = 0.65 mg VSS/mg soluble BOD

kd = 0.05

volatile MLSS = 1600 mg/L

The influent total BOD = 375 mg/L with a soluble BOD= 260 mg/L.

The design effluent total BOD = 30 mg/L with a soluble BOD = 9.0 mg/L.

Aeration tank volume:

Aeration period:

F/M:

Excess biomass in the waste activated sludge per day:

(Px = volatile solids in the waste sludge, g/day)

The rate of sludge production:

Assuming the solids are 80% volatile, total production would be;

Assume the underflow solids concentration; Xr = 15,000 mg/L.

The hydraulic retention time in the reactor is;

O2 demand:

Calculate the volume of air to be supplied:

At standard condition:

T = 20oC

Pressure = 1 atm

Air density = 1.185 kg/m³

% Oxygen by mass in air = 23.2% = 0.232

Assuming 100% oxygen transfer efficiency:

Assume 7% oxygen transfer efficiency:

Figure 1: Diagram of facility.

Figure 2: Seeb STP _ MPS 1

3. Operational aspect of the wastewater treatment plant:

3.1 Physical Therapy:

At the beginning of the wastewater treatment plant, the effluent is pumped from the pump. Two ventilated tanks will then be inserted into the ventricle where they are activated by the use of coarse bubble diffusers for three reasons:

Reduction of septicity.

Prevent the settlement of solids in the sewers.

There are three numbers of centrifugal blowers which are supplying air to the aerobic tanks, and MPR tanks.

Remove objects by using a drum.

Drum screens are provided with laundry water pumps.

Remove materials that float and cause nuisance in the downstream process.

The blower is used to supply air to different areas: eg, before venting tank.

Pump water from drainage to the channel entrance screens for the drum, by using a recycled pump and a drainage pump to retract.

3.2 Tertiary/ Chemical Treatment Processes:

Odor and gas control unit: This unit consists of hydrogen sulfide, ammonia and the removal of gas it is filled with ventilation tanks by washing chemicals.

In addition, caustic soda doses are provided to adjust the pH of the liquid.

6 TE Pumps available and 2 more will be in operation in Phase 2.

The Plant follows standard A Treated Effluent Specification.

Finally, water is pumped into the water system, for example, irrigation networks and loading of oil tankers.

Figure 3:Sludge Treatment Unit Figure 4: Tertiary Treatment Unit

3.3 MPR Technology:

The membrane bioreactor (MPR) is a combination of a membrane process such as micro filtration with a bioreactor. And the industrial waste water treatment capacity of the sewage treatment plant reaches 48 million liters per day.

Figure 5: MPR

4. Environmental significant:

Working in Haya is a job because it focuses on all their efforts towards the environmental goal by following the principles of the environment.

This project is one of the engineering projects to reuse wastewater treatment. Therefore, its success will affect Omani development as awhole and not just Muscat.

For example, health issues, and pollution produced, will be improved, traditional sanitation systems are reduced, and some diseases are reduced, groundwater conserved and protected from pollution.

One example of an ecological organization is the “Kala Compost”. Is the natural Omani company made of (biosolids) taken from waste water and green waste, for example tree leaves and branches.

Kala Compost is produced in Haya Water Factory which is located in Al-Amerat in Muscat Governorate and has a capacity of 40 and 000 tons of fertilizer annually. Fertilizer is tested in vitro at the factory's pre-market location. They are packaged in eco-bags and are decomposable and available in 10 liters, 20 liters, 50 liters, bags showing product images manufactured and their results in plants.

4.1 Problems that occur to the environment and the reason for the filtering process:

Chemical harmful additives for workers.

The high flow is insufficient for treatment and is transported to the sea and this harms health.

The number of fine screen is enough.

4.2 Ministry of environmental and climatic affairs:

| Parameter | System | Unit | Use in irrigation | |

| Standard A | Standard B | |||

| PH | PH | - | Rang 6-9 | Rang 6-9 |

| Total suspended solids. | TSS | µs/cm | 15.0 | 30.0 |

| Total Dissolved solids. | TDS | m/l | 1500.0 | 2000.0 |

| Nitrite Nitrogen. | N- NO3 | mg/l | - | - |

| Nitrate. | NO3 | mg/l | 50.0 | 50.0 |

| Chloride | CL | mg/l | 650.000 | 650.000 |

5. Conclusion:

Project supports the expansion of the seeb Sewage treatment Plant in Muscat, Oman. This project includes the expansion of the second phase, with a circulation of 20,000 cubic meters per day. In addition, the capacity of the sewage plant is increased from 62,000 cubic meters per day to 82,000 cubic meters per day. In order to accommodate larger quantities of sewage in the Seeb. In addition this project includes the construction of a sewage treatment plant with a maximum capacity of 80 thousand cubic meters per day. It also includes 3 pumping stations, treated wastewater storage tanks and a 3.5 km long seawater pipeline. Also the flow is always done through the networks of houses and construction. The various treatment units are controlled by the control room in a manner equipped with sophisticated and advanced techniques that help to monitor the operation of the treatment process continuously and efficiently. Moreover, at the sewage plant in Sip, different samples of the treatment units are collected on a daily basis and the necessary tests are carried out for the purpose of evaluating the efficiency of the treatment process.

6. Reference:

Bncnetwor, 2016, Seeb-Sewerage-Treatment-Plant. [Online]. Available at https://bncnetwork.net/...Seeb-Sewerage-Treatment-Plant [Accessed on 20/11/2017].

Parsons, 2014, Aseeb-wastewater-project. [Online]. Available at .https://www.protenders.com [Accessed on 20/11/2017].

Pretenders, 2o17, tanks seeb sewage treatment.[Online].Available at https://www.protenders.com [Accessed on 2/12/2017].

Ssiaeration, 2016, Design wastewater treatment plant. [Online]. Available at www.ssiaeration.com/sewage/treatment [Accessed on 1/12/2017].

17| Page