Help ! ASAP by tonight please :))

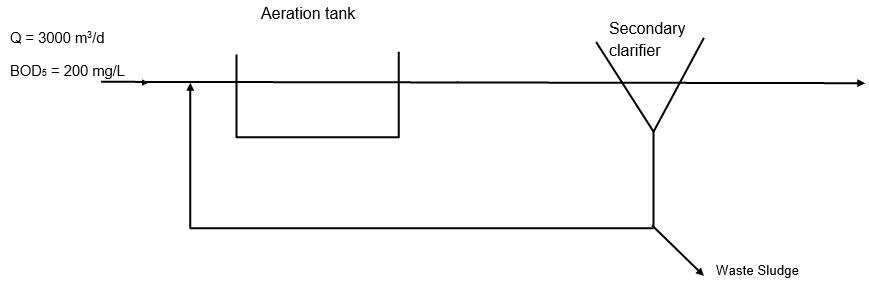

Wastewater containing BOD5 of 200 mg/L is to be treated via activated sludge process. With a wastewater flowrate of 3000 m3/d, design a complete-mixed activated sludge process in fulfillment of the following criteria during the commencement of the treatment.

Aeration Tank:

F/M ratio = 0.25 – 5.00 kg BOD5/MLVSS.d

Mean cell residence time (MCRT) = 5 – 10 d

Hydraulic retention time = 5 – 7 h

MLSS concentration = 4000 – 6000 mg/L with 75% consisted of volatile matter

Recirculation ratio = 0.4 – 1.0

Required effluent BOD5 = 20 – 25 mg/L

Excess sludge wastage rate = 0.5 – 0.8 kg/kg BOD5 removed

Secondary Clarifier:

Hydraulic loading = 35 – 50 m3/m2.d

Depth of clarifier = 3 – 6 m

Solids loading = < 150 kg VSS/m2.d

The schematic system to accommodate a complete-mixed activated sludge process is shown as below:

Your design information must be able to answer the following questions:

What is the volume of aeration tank as calculated from F/M ratio?

What is the diameter of secondary clarifier as calculated from recirculation ratio?

From the diameter of secondary clarifier, what is the suitable volume for secondary clarifier to satisfy the depth range criterion?

NOTE: All the ASSUMPTIONS made must be explicitly stipulated along the designing steps.

ATTACHMENT 1