Risk Management PlanNote: The assignments in this course are a series of papers that are based on the same case, which is located in the XanEdu tab in the left-hand menu of your course. The assignment

Running head: Assignment 1: Access Organizational Readiness.

Assignment 1: Access Organizational Readiness

Introduction

The "British Petroleum (PLC) and Lord John Browne: A Culture of Risk Beyond Petroleum" case study concerns the company's 2005 explosion at its Texas City Oil Refinery, where 15 people were fatally wounded, and 180 others were critically injured. Several investigation findings were released after the incident that established the company's damaging record, including the ill-regulated safety practices of the plant and risk management. This paper will record my evaluation of the case study and examine how the Critical Success Factors (CSFs) contribute to the case study facts, describe the company's project gains, operational readiness, and risk culture, establish three project risk guidelines based on the research done, and eventually identify the initial risk categories (RBS Level 1 and 2) as they refer to the thesis.

Analysis of Critical Success Factors

CSFs can be better defined as the main areas of operation that must be carried out effectively if the project is to accomplish its mission, priorities, and or targets set. A general point of reference within his or her project can easily be defined by the Project Manager (PM) to better track and assess the project's progress by evaluating the CSFs. It is also possible to put aside all the most traditional explanations and excuses for not applying risk management to a project by concentrating on the project CSFs. The CSFs that refer to this case study include incorporating process safety, engaging in maintenance, recording security protocols and procedures, making all management responsible for the success of process safety, and maintaining a single process safety culture for all U.S. refineries (MindTools, 2017). e.g., James Baker's (U.S. Chemical Safety and Hazard Investigation Board) released a study after the accident at the Texas City Oil Refinery, where the CSFs found were not upheld or where non-existent were defined. Mr. Baker's study noted many occasions where B.P. appeared to neglect general safety-related processes such as compliance that were not present at the top management level, no safety leadership mechanism introduced, and the lack of appropriate leadership by the organization to ensure that the whole team knew and conformed to safety results.

The Project’s Benefits, Organization Readiness, and Risk Culture

Project’s Benefits

The advantages of the initiative were clear, dramatically raising profit for the enterprise and its stakeholders. However, it lost track of those vital elements that could make or break a corporation in the company's effort to do so (i.e., risk recognition, safety practices and processes, taking care of employees, upper management awareness). The firm forfeited protection in order to retain its lead in the petroleum sector, resulting in diminished trust among customers, placing their worker's lives at risk, reducing the credibility of the company dramatically, culminating in the loss of an immense amount of money in the company. It was felt that the services of the company were sacrificed for better benefits and cost savings.

Organizational Readiness

B.P.'s operational preparation was assumed to be satisfactory, but it was later revealed that it was not to the degree required for the project's progress. While Lord Browne (B.P. Group Chief Executive) was recognized as one of the U.K.'s most admired business leaders and recognized for saving the company and getting B.P. to the oil industry's peak point, it was clear that he was also responsible for the company's poor safety performance. Being known for negotiating deals and cutting prices, Mr. Baker admitted that Lord Browne did not apply the company's protection culture to establish a suitable approach to meet the organization's objectives (Hillson, 2012).

Risk Culture

It is best to define the risk culture as the ideals, opinions, awareness, behaviors, and perception of risk expressed by a community of people with a common intent (irm, 2017). It seems like the risk culture at B.P. was missing. The company's constant cost-cutting, manufacturing stresses, lack of infrastructure spending, lack of proactive maintenance, and lack of sufficient training suggest that the company's risk culture was deficient and indistinct. This is clear that the company did not put protection first, thereby compromising its workers' lives. All the risks involved with the project would have been defined upfront and better handled over the project's life if a proactive risk culture had been in place at B.P.

Project Risk Recommendations

There are some guidelines on project vulnerability that should be applicable to this project. I have decided to represent designing and adhering to a risk management strategy, implementing protection as a priority, producing and managing all relevant records, and hiring a risk management administrator.

Risk Management Plan

The development and execution of an appropriate risk management strategy by B.P. is crucial. The Risk Management Strategy is often avoided or perceived as a lesser priority for any project's essential aspect, resulting in tremendous impacts on the project. The PM will create a Risk Assessment Strategy after the project's risks have been identified. The paper will provide a risk appraisal summary and describe the recommended solutions or mitigation measures that will be implemented over the project life cycle. The purpose of the Risk Management Plan is to document the risk control approach for each risk defined to eliminate or mitigate the risk effectively.

A project must have comprehensive. A project must have a comprehensive Management must ensure that the strategy is thoroughly executed and adopted by the project team to ensure cohesive risk reduction methods within the enterprise.

Safety is a Top Priority

For the whole company, B.P. has to ensure that protection is a top priority. The related protection protocols must be established and managed by the top management of the organization to ensure that the records are accessible and accepted by the project leaders and their team members. Security management is a high-priority, organized mechanism that forces an agency or initiative to handle safety efficiently.

Risk Management Manager

A top-level executive risk management manager is expected by B.P. to be hired. This employee will report directly to the Chief Executive Officer (CEO) and will execute a risk management policy that is effective and effective. The chosen person would initiate and thoroughly record measures in order to conform with safety laws and industry standards. The risk manager will study and report on the most cost-effective risk liability policies to mitigate asset-liability.

Initial Categories of Risk

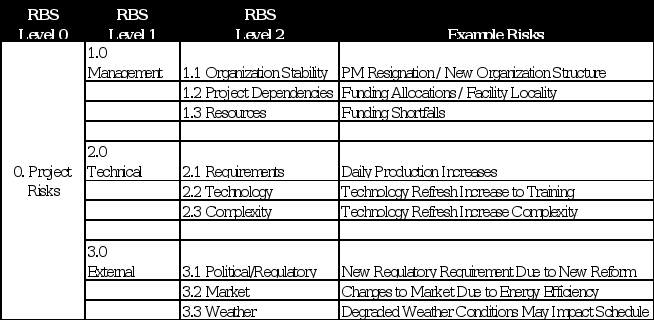

The Risk Breakdown Structure (RBS) is a helpful method to facilitate a PM in handling defined risks (EDUCBA, 2017). The RBS starts with the description of the higher-level risks as a structural representation of risks and goes down to the lower-level risks. British Petroleum (PLC) and Lord John Browne chose the original categories.

References

EDUCBA. (, 2016). 6 Basic Steps to Develop a Project Risk Management Plan. EDUCBA. Retrieved from https://www.educba.com/project-risk-management-plan/

Institute of Risk Management. (, 2017). Risk Culture. irm. Retrieved from https://www.theirm.org/knowledge-and-resources/thought-leadership/risk-culture.aspx

Hillson, David. Practical Project Risk Management: The ATOM Methodology, 2nd Edition. Management Concepts Press NBN, 2012. [Strayer University Bookshelf].

MindTools. (, 2017). Critical Success Factors. Retrieved from https://www.mindtools.com/pages/article/newLDR_80.htm