operation managming work

Answer the case given below:

Abbas Engineering is doing job shop services. Over the past 10 years, it has served so many clients. Mr Abdulla, who handles the job shop scheduling, is following the system, which has been used for the past years. The elders who used to handle the operation processed the customer requirement based on how they arrive in the shop. However, over the past years, customers are complaining for failure to complete the jobs on the required time. With this, Mr Abdulla thought of hiring expert who can improve the performance of the company. The first applicant, Mr Hashim is proposing to use Johnson’s rule in improving the completion time and reducing the idle time.

The 2nd applicant , Mr Hussain is proposing to use the First Come First Serve basis in processing customer requirements. Each job needs to be processed in 2 work centers A and B. With the data provided below :

| Client | Work Center A ( days ) | Work Center B ( days) |

If Johnson's rule as being pushed by Mr Hashim, what will be the completion time and idle Time . ( 3 pts for the sequence, 5 pts for the diagram , 2 pts for the completion time and 3 pts for the idle time)

If Mr Hussain's suggestion will be followed, what will be the completion time and idle Time ( 3 pts for the sequence, 5 pts for the diagram , 2 pts for the completion time and 3 pts for the idle time)

If you will be given the chance to recommend between the two applicants, whom will you recommend and why and on what basis have you arrived at that recommendation. ( 10 pts

Part a:

Steps for Johnson’s Rule (six jobs)

For “n” jobs on two machines, the steps to follow for Johnson’s rules are:

1. From the list of unscheduled jobs, select the job with the shortest processing time on either workstation (WS).

2. If the shortest time is at WS-1, schedule the job for the first slot in the schedule or at the last slot in the schedule.

3. Remove the job assigned in step 2 from the list of unscheduled jobs.

Repeat steps 1, 2, and 3 until all jobs have been scheduled.

Let Document review operation represented by WS#1 and luggage inspection operation by WS#2

Sequencing:

The lowest process time of Job #C is 1 at the M/C#2, thus, sequence the #C at 6th position. Remove #C from the list.

The lowest process time of Job #D is 2 at the M/C#1, thus, sequence the #D last at 1st position. Remove #D from the list.

The lowest process time of Job #E is 3 at the M/C#1, thus, sequence the #F at 3rd position. Remove #E from the list.

The lowest process time of Job #F is 4 at the M/C#2, thus, sequence the #F at 5th position. Remove #F

The lowest process time of Job #A is 5 at the M/C#1, thus, sequence the #E at 3rd position. Remove #E

Remaining job B is sequenced at 4th position

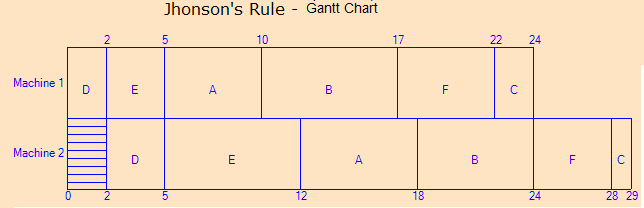

The Gantt chart for the sequence is as follows:

The total idle time is 2 days

The completion time of the schedule = 30 days

Part b:

First, come-first serve sequencing:

According to FCFS, the jobs will be sequenced according to their arrival. Thus, the sequencing will be as follows:

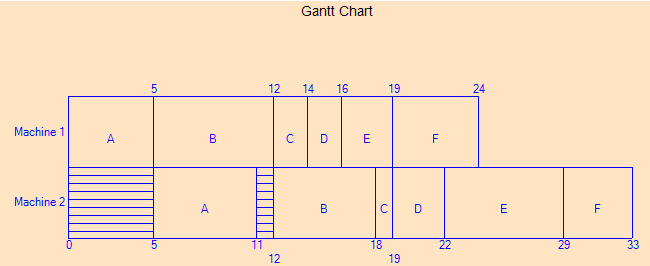

The Gantt chart is as follows:

The total idle time is 5+1 = 6 days

The completion time of the schedule = 33 days

Part C:

Since the idle time and completion, time by Johnsen’s rule is lower than FCFS rule; to minimize the idle time and completion time sequencing by Johnsen’s rule should be preferred.