Description In this assignment, students will critique another student’s analysis of a previously developed case study. Instructions On MONDAY of this unit, you will be assigned a partner with w

12

Running head: Case Study Report 3

Research Project Part 3: Case Study Report

Name – Simrat Kaur

Student Id – 2018100225

Busi 4013 Business Organization Analysis 11/11(22W-C-BC_9C)

Professor – Thomas Jones

Yorkville University

February 10th 2022

Introduction

Enbridge Inc. is a leading North American energy company, with a strategic business platform that includes a large network of crude oil pipelines, liquids, and natural gas pipelines, as well as regulated resources for natural gas distribution and renewable energy generation(Enbridge,2022). Calgary, Alberta, Canada is home to the company's headquarters and it was founded in 1949(Enbridge,2022). Through the Mainline and Express Pipelines, the Company safely transports 2.8 million barrels of crude oil per day; comprises approximately 65 percent of Canadian crude oil exports to the United States; and transports about 20 percent of all natural gas used in the United States, providing essential services and demand markets(CNNews,2019). In Ontario, Quebec, and New Brunswick, the Company's controlled services serve approximately 3.7 million retail customers. Enbridge also owns more than 2,500 MW renewable energy sources in North America and Europe(CNNews,2019). For the past nine years, the Company has been included in the Global 100 Most Sustainable Corporations index; their regular shares are traded under the ENB brand in the Toronto and New York stock markets(Enbridge,2022). In the paper the case study about the Nestle supply chain was analyzed and after it is compared to the Supply Chain Management of Enbridge Inc. Moreover, this paper will describe Enbridge Organizational Structure, the supply chain framework of Enbridge Inc., Lifecycle process of an Enbridge Pipelines Inc.

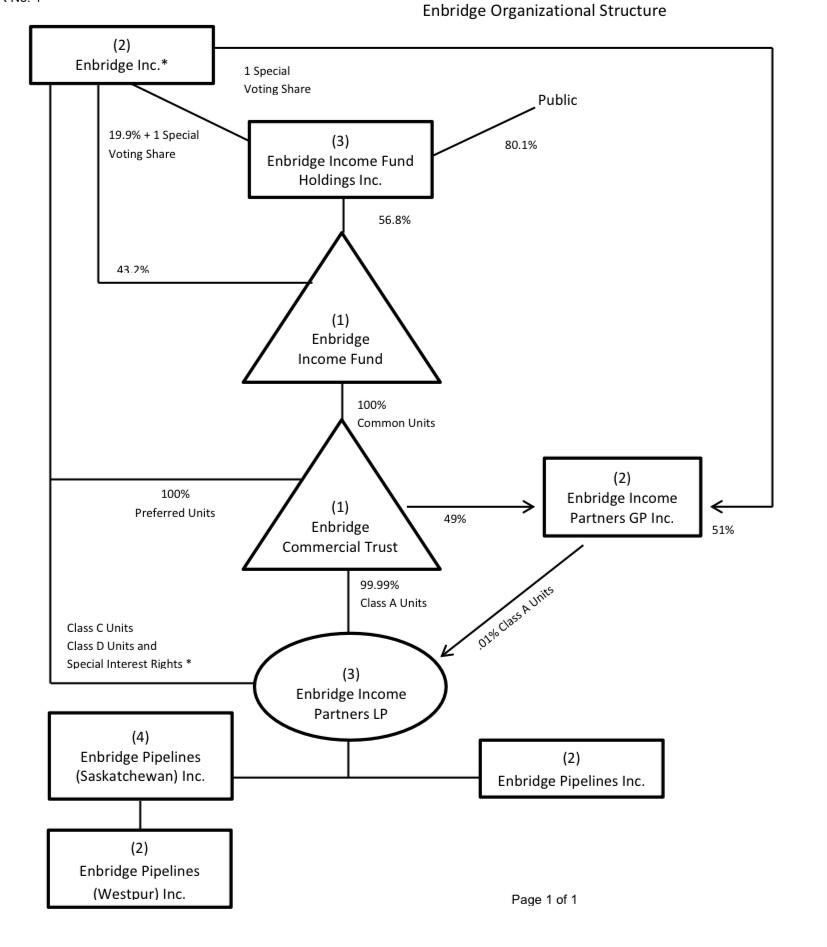

Enbridge Organizational Structure

(Enbridge,2017).

Description about Enbridge Organizational Structure Chart:

(1). An unincorporated trust governed by the laws of Alberta.

(2). Incorporated under laws of Canada.

(3). Incorporated or established under the laws of Alberta.

(4). Incorporated under the laws of Saskatchewan(Enbridge,2017).

Supply Chain Management

Enbridge Inc.'s supply chain, which includes contractors, subcontractors, vendors, and consultants, plays a key role in the company's ability to meet its social responsibility obligations and achieve its sustainability goals(Enbridge,2017). To that end, they seek out industry-leading providers, ready to uphold their core values of honesty, safety, and respect, adhere to their core policies and procedures, including the Enbridge Statement of Business Ethics, and share their commitment to the highest standards(Enbridge,2018). In addition, their policies and management systems Supply Chain Management (SCM) continue to prioritize the provision of opportunities for Indigenous socio-economic participation. There are Four Performances Objectives are as follow:

Procurement of goods and services that meet their environmental management standards.

Increasing opportunities for local businesses, small and medium enterprises, to participate in their supply chain(Enbridge,2017).

Increasing opportunities for Indigenous peoples to participate in their socio-economic delivery program.

Purchase goods and services that meet their safety and ethical requirements(Enbridge,2018).

Management Approach

They work with tens of thousands of providers across North America, from large international companies to small local businesses. Their suppliers cover a wide range of fields, including manufacturing, construction, engineering, distribution, and consultation, but pipeline production, construction of their pipelines and services, maintaining the efficiency of their systems, and monitoring to ensure the integrity of their systems for the bulk of their annual revenue(Enbridge,2018).

SCM Structure

They have a single, mid-range SCM function that works for the entire company. Oversees all areas of supply chain management, from planning and management to procurement and logistics management, contract management, and strategic acquisition, with the aim of maximizing the value of Enbridge and partners(Enbridge, 2018). Their SCM work also consists of staff working in one place to help us integrate Indigenous interactions, as well as other environmental and social considerations and opportunities, in their SCM programs and activities.

SCM Governance

All of Enbridge's SCM operations are governed by its core values of integrity, safety, and respect, as well as various policies and procedures, which they continually update and improve as their business grows(Enbridge, 2017). Here are some examples of governing documents: Supplier Code of Conduct, Business Ethics Statement, Corporate Liability Policy, Indigenous Policy, SCM Policy, and Purchasing Control Policy are also available(Enbridge,2018).

How SCM Integrates Environment, Social and Governance Factor

Their SCM processes are designed to acquire goods and services that meet our environmental, social, and ethical requirements. achieve this goal by incorporating environmental, social, and governance (ESG) factors into their choice of providers and relationship management processes, including pre-qualification, proposal applications (RFPs), proposal assessments, contracts, and provider performance management(Enbridge,2018).

Lifecycle Process of an Enbridge Pipeline Inc.

Design and Construction

Enbridge's power infrastructure is designed to be safe and reliable before, during, and after construction. As they build pipeline projects, they make sure to minimize their track record and actively manage any consequences to communities and the environment(Enbridge,2017). They use existing routes to and from construction sites whenever possible, minimizing temporary workloads and minimizing ground disturbances(Enbridge,2022).

Field Surveys and skating

To better understand the environmental, development, and environmental challenges, field surveys are conducted in a systematic manner (ROW). The area is marked with poles when the route is completed(Enbridge,2017).

Working with landowners

They are working with landowners to develop project-specific biosecurity systems, which include keeping all of their equipment clean and free of weeds, soil, and debris(Enbridge,2022). Depending on the amount of hazard in the construction site, they also take steps to control and control weeds and soil-borne diseases(Enbridge,2017).

Grading

The bottom ROW along the ROW is planned to allow for the construction of safe pipelines once the topsoil has been excavated and stored for data purposes

Bending

Workers bend the pipe sections to meet technical standards and follow international concerts.

Welding

Through well-selected and tested tubes, the pipe is welded to pieces and eventually into a long section. X-ray or ultrasound equipment is used to examine each weld.

Coating

A corrosion inhibitor is applied to all parts of the pipe, including the welding joints.

Lowering-in

The pipe is lowered into the ditch using multiple side-booms or cranes.

Trenching

The drainage ditch is dug with backhoes or wheel ditches.

River Crossings

Pipes are placed under major rivers or in critical areas using horizontal directional drilling (HDD) technology.

Backfilling

The subsoil is carefully filled and covered with trench.

Hydrostatic testing

To ensure the strength of the pipe and welds, each section is filled with water and is subject to high operating pressure.

Cleanup and Reclamation

ROW has been restored to its original condition. Other restoration methods include planting trees and monitoring the environment, as well as replacing and replanting the topsoil(Enbridge,2022).

Operations and maintenance

Once the pipe is installed, it has a high life expectancy due to safe operation. Preventive, monitoring, and rehabilitation activities are all important(Enbridge,2022). They strive to meet or exceed expectations. In the United States and Canada, safety and reliability laws are in place(Enbridge,2017).

Decommissioning

Enbridge pipes shut off or closed are not the responsibility of landowners.

Safety

Lastly, they may want to look at all the ways in which Enbridge works to ensure public safety in all their facilities and services as they look at what they are doing to better plan, build, operate, and repair pipelines(Enbridge,2017).

Conclusion

To conclude, they work closely with their suppliers and them accountable to the same environmental, social, ethical and safety standards to which they hold themselves. The corporation with exact control in the supply chain is much more likely to attain their desires both short-term and long term (Moodle, Zoom ,2022). Moreover, the supply chain case of Nestle was helpful to analyze the supply chain of Enbridge Inc. (Business Case Studies, n.d.). Supply chain of Enbridge Inc. is not similar to Nestle coffee. Their lifecycle process is totally different because they processed crude, Natural oil pipelines, Liquids and many more renewable energies and soon. As the supply chain of Enbridge Inc. business is complex. They meet the demand of their expansion operations across North America, their rely upon a network of suppliers and contractors to help them construct pipelines and facilities, provide needed equipment and supplies, they deliver specialized expertise and serve customers and other stakeholders.

Reference

Business Case Studies. (n.d.). Coffee - The supply chain: A Nestlé case study. Business Case Studies. Retrieved from https://businesscasestudies.co.uk/coffee-the-supply-chain/

(Moodle, Zoom February 7, 2022).

Enbridge, I. (2018.). Supply Chain Management. Home - Enbridge Inc. Retrieved February 12, 2022, from https://www.enbridge.com/sustainability-reports/sustainability-report-2018/areas-that-enable-continuous-improvement/supply-chain-management/supply-chain-management

Enbridge, I.(2017.). Supply Chain Management. Home - Enbridge Inc. Retrieved February 12, 2022, from https://www.enbridge.com/sustainability-reports/sustainability-report-2017/areas-that-enable-continuous-improvement/supply-chain-management/supply-chain-management

Enbridge, I. (2017.). Enbridge Pipelines Inc. (“Enbridge ... - docs.cer-rec.gc.ca. Enbridge Organizational Structure . Retrieved February 12, 2022, from https://docs.cer-rec.gc.ca/ll-eng/llisapi.dll/fetch/2000/90464/90552/92263/790736/890819/918445/1035280/B42-7_-_Attachment_6_-_Revised_Response_to_NEB_IR_No__3.1.a__A3K9R4_.pdf?nodeid=1035533&vernum=-2

Enbridge, I. (2022). The lifecycle of an Enbridge pipeline. Lifecycle of an Enbridge Pipeline - Enbridge Inc. Retrieved February 12, 2022, from https://www.enbridge.com/projects-and-infrastructure/public-awareness/pipeline-lifecycle

Yorkville , U. (2014). Busi 2014 Business Organization Analysis Project . courses.yorkvilleu.ca. Retrieved February 12, 2022, from https://courses.yorkvilleu.ca/pluginfile.php/1822168/mod_forum/attachment/1008682154/BUSI_4013%20Coursepack.pdf

CNN, B. (Ed.). (2019). Enbridge Inc. CNNMoney. Retrieved February 12, 2022, from https://money.cnn.com/quote/quote.html?symb=ENB

Enbridge, C. (2022). Company overview. Company Overview - Enbridge Management. Retrieved February 12, 2022, from https://www.enbridgemanagement.com/About-Enbridge/Company-Overview.aspx