Apple Operations Management

Running Head: VICE PRESIDENT OF OPERATIONS, PART 2 0

Vice President of Operations, Part 2

Isaura Perry

Strayer University

BUS515: Operations Management

Dr. Phyllis Parise

February 12, 2017

Assignment 2: Vice President of Operations, Part 2

Due Week 6 and worth 280 points

Refer to the scenario from Assignment 1.

Write a six to eight (6-8) page paper in which you:

Evaluate two to four (2-4) weaknesses that are evident in the selected organization’s product life cycle. Generate a new product design and process selection, and then determine three (3) strategies that the organization needs in order to strengthen the operation. Provide support for the rationale.

Determine the key components of supply chain management for the company you have selected. Determine three (3) major issues that could affect the structuring, sourcing, purchasing, and the supply chain of your organization. Provide a solution to each issue.

Develop a total quality management tool that identifies and analyzes any future issues. Provide a rationale for developing the selected tool.

Analyze three (3) advantages in employing the just-in-time philosophy in your organization. Evaluate three to five (3-5) means in which the philosophy could potentially impact quality assurance. Provide specific examples to support your response.

Determine a qualitative and quantitative forecasting method for your operation. Next, create a table in which you identify the characteristics of the operation that relate to each method. Evaluate the strengths and weaknesses of each method.

Use at least three (3) quality academic resources in this assignment. Note: Wikipedia and other Websites do not quality as academic resources.

Apple Inc’s Operations Strategic

The concept of product life cycle has been around for a very long time. Product life cycle describes how the sales of products evolve over a period. This concept states that just like living organisms, products pass through four stages in their life. These stages are the introduction, growth, maturity, and decline stage. Apple Inc. has taken advantage of these four steps to maximize the profitability of its products over its lifetime. To maintain Apple’s competitive edge, its Vice President of Operations Isaura Perry will evaluate Apple's product life cycle weaknesses and generate a new product design and process selection, and then determine the strategies that Apple will need to strengthen their operation. Then, she will determine Apple's supply chain management fundamental components and the major issues that could affect the structuring, sourcing, purchasing, and the supply chain of the company. Following, she will develop a total quality management tool that will identify and analyze any future issues. Next, she will examine the advantages in employing the just-in-time (JIT) philosophy and how could potentially impact quality assurance in Apple. Last, Vice-President of Operations Isaura Perry will determine a qualitative and quantitative forecasting method for Apple and identify the strengths and weaknesses of each method and the characteristics of the operation that relate to each approach.

Apple’s Product Life Cycle

Weaknesses of Apple’s product life cycle

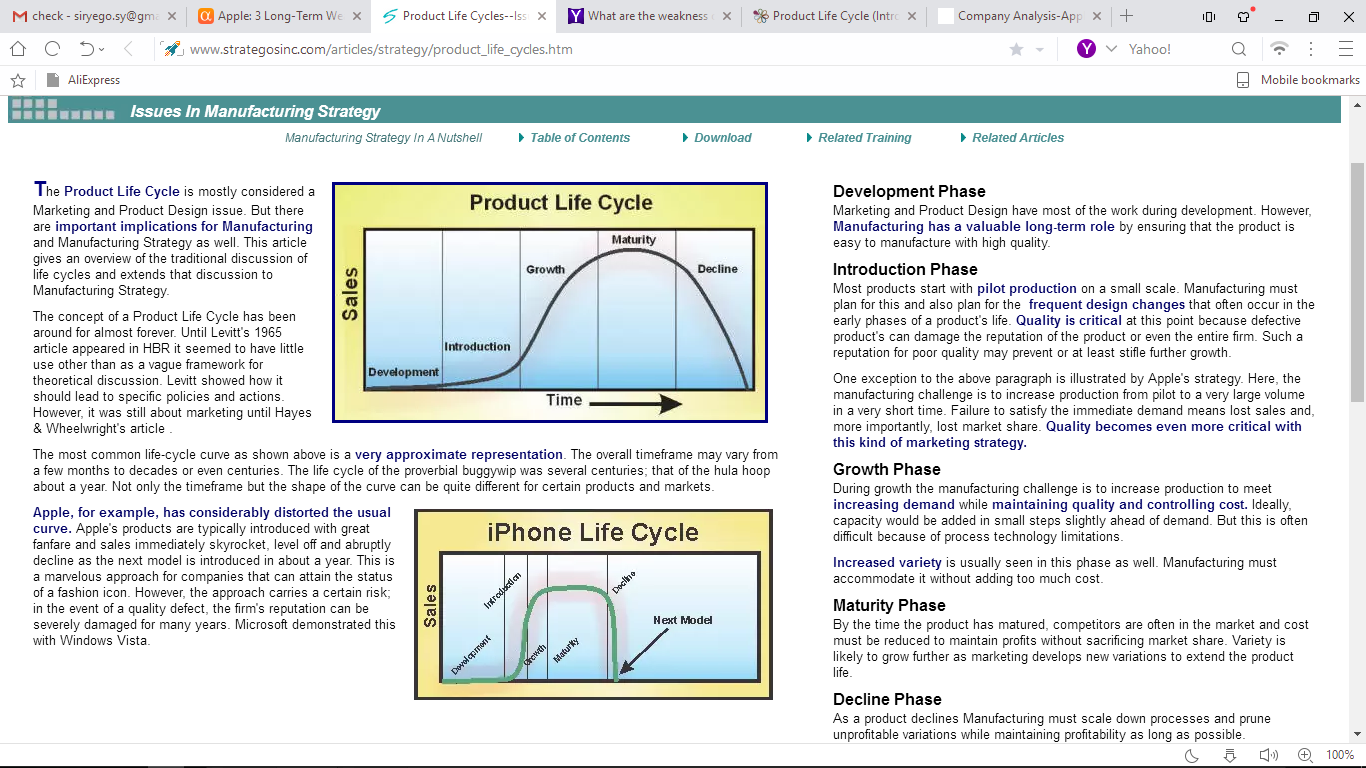

Figure 1. The Approximate representation of a common life cycle.

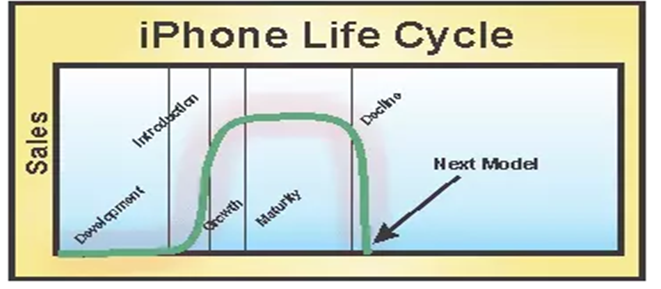

Figure 2. Apple’s short product life cycle.

The figure above represents an approximate representation of the most common life cycles. Apple has a rather distorted curve. Apple’s products are always introduced with lots of expectation and fanfare. It, therefore, follows that sales skyrocket immediately after the products are released into the market. This approach has proved ideal for firms that can attain and sustain the status of a fashion icon. However, such a product life cycle carries with it an absolute risk. A defect in the product can have a harmful effect on the firm’s reputation.

Apple’s product life cycle is very short, and this may discourage customers. Apple does not just sell electronics. It also sells a lifestyle. Over time, Apple has succeeded in developing a “cult following” for its high-end products. Therefore, the consumer backlash is seen as strong when the product is seen as last year’s “hot product.” By a similar token, the backlash from investors will be vehement when a product fails to meet their expectations.

Another weakness relates to the fact that Apple’s operating system does not integrate well with outsider’s hardware. While Apple does this to maintain their design standards and to keep the design control in-house, the adaptation of its software to other computers has been severely hurt, and this has led to a relatively small market share.

The firm’s product development cycle heavily depends on the supply of products from IBM. In case IBM experiences manufacturing problems, then the problems would naturally extend to Apple thus the risk of losing its customers. Over dependency on a secondary firm may lead to a competitive disadvantage.

New product design and process selection to improve Apple

Just like any other firm, there are cases when Apple’s forecasting about demand is erroneous. A reduction in demand forces the company to reduce the production of the affected products. The decrease in demand also affects the supply of finished goods to the customers because of the reduced availability. Therefore, Apple must strive to maintain the sustainability of its products in the market.

The current and future success of Apple can be attributed to its unique design and selection process. To continuously deliver high-end quality products, Apples should consider integrating design thinking with user-led product solutions.

The strategy will focus on the following elements;

A focus on user experience as the primary factor in the development and selection of Apple’s products.

Consolidating the efforts of designers with that of product development teams.

A user-centric product development cycle. This can be broken down into five crucial stages.

Understand. This is a phase of information gathering that aims at giving designers a deep insight into consumer preferences and address issues of product users. This step makes critical initial observations.

Envision. This is where designers brainstorm about the services they may offer to the users. This phase produces new insights and conceptual breakthroughs.

Specify. This is where designers and product development teams develop a design specification for the product they have unanimously agreed to create.

Implement. This entails all steps in the manufacturing process that aim at delivering a high-quality product to the customer.

Maintain. The products are regularly modified to match changing needs of consumers. Therefore, the product design team plays the role of providing continuous input into modifications throughout the products life cycle.

Supply Chain Management

Apple’s key components of supply chain management and issues that could affect the structuring, sourcing, purchasing, and the supply chain of Apple.

Supply chain management is a very critical section of any firm since it facilitates the delivery of goods from the inventory to the customers to ensure satisfaction of their needs (Arndt, 2004). Apple’s supply chain management can be categorized into five major steps. These are sourcing, manufacturing (assembly in China), warehousing, distribution, and retail. In a nutshell, Apple purchases sources materials and components from various suppliers then ship them to its assembly plant based in China. The products are then delivered to customers who buy the products through the firm’s online store. Apple also uses alternative distribution channels such as direct sales, other distributors, and retail stores. The company’s central warehouse is located in Elk Grove, California and supplies products from there (Apple, n.d.).

In as much Apple’s supply chain looks well structured; it still has its downsides. There are still many challenges to overcome. In the recent past, Apple has been plagued by supply problems. The firm has had components come in late such as Airpods whereas others like Apple TV have come in a little constrained. These challenges result from inaccurate demand forecasting or lower yields than expected. Other times it is just about last minute changes to manufacturing processes. The firm needs to address miscues in its forecasting to obtain a better balance with its supply chain as well as image problems that may significantly affect sales. Although most components essential to Apple’s manufacturing process are sourced from diversified suppliers, key elements such as optical drives, microprocessors and liquid crystal displays (LCDs) are still sourced from single or limited sources. This exposes the firm to substantial supply risks since these components are subject to price fluctuations and shortages that can adversely affect its operations and profit margins. To solve this problem, the firm should consider the possibility of diversifying its supplier base to cushion itself against the shortcomings of its suppliers.

Creating a new brand comes with the need to source new materials or parts. However, suppliers are not always familiar with that particular brand. The result is that providers may fail to produce the components Apple needs promptly and this may slow the production process. To jump this hurdle, the firm should leverage supplier technology to keep tabs on delivery performance, production and yield rates and compliance factors.

Total Quality Management Tool

Quality management ensures that a company produces goods that are consistent. It is an essential part of the production process that entails overseeing all activities to maintain a desired standard or level of excellence. Traditionally, quality management concentrated on quality control whereby goods were inspected at the end of the production and inferior products regarded as “waste” sold at a lower price or disposed of. Over time, many tools and ideas have been created to eliminate waste completely and ensure the highest standards are always realized.

For improving the total quality management, Apple should employ the Flowcharts and Modeling Diagrams and the Plan-Do-Check-Act.

Flowcharts and Modeling Diagrams

Assist in the definition and analysis of each step in a process by illustrating it in a clear and comprehensive manner.

Identify areas where the workflow may be blocked, or diverted, and where the workflow is fluid.

Determine where steps need to be added or removed to improve efficiency and create a standardized workflow (Berk & Berk, 2000).

Plan-Do-Check-Act (PDCA)

Each project or procedure is planned per needs and outcome, it is then tested, examined for efficiency and effectiveness, and then acted upon if anything in the process needs to be altered. This is a cyclical style to be iterated until the process is perfected.

Flowcharts and Modeling Diagrams and the Plan-Do-Check-Act management tool can be easily created and examined by using various types of computer software or by simply mapping them out on paper. They can also be easily integrated into team meetings, organizational newsletters, marketing reports, and for various other data analysis needs. Proper integration and use of these tools will ultimately assist in processing data, enhancing workflow, ensuring client satisfaction and creating an overall high level of quality in all areas of Apple.

Advantages of Just-In-Time (JIT)

Apple can accrue the following advantages by implementing a Just-In-Time JIT philosophy.

The development of a homogeneous workload plan. To reduce the delays in the supply chain, Apple can effectively distribute its workload between different workstations. The firm can manage its inventory by calculating the required quantity of the needed raw materials for manufacturing the next products in the production line (Cheng & Podolsky, 1996).

Just-in-time (JIT) philosophy can help reduce the overall production time and the timing of delivery products since it enhances the cooperation between operational processes (O'Grady, 2012).

Another advantage of JIT is that it can significantly reduce the setup time required to make changes to an existing production process to come up with quality products in the shortest time possible. Researchers argue that there is a correlation between JIT and the quality of goods. This is because JIT integrates quality control with the operational process. Furthermore, JIT enables the organization to identify technical faults before the production process thus providing them with an opportunity to rectify the problem and improve the quality of the final products. This is of importance because it forces the production personnel to employ their best practices. When this is done, the workers reduce their error margin and substantially improve the quality of their products.

JIT impacts quality assurance in the following ways:

Continuous improvement.

Through JIT, a firm can remove steps and processes that do not add value to the final product.

Come up with mechanisms to detect and identify problems.

Quality control at the Source. This is where workers take responsibility for their input in the production process.

Preventive maintenance to optimum performance of machinery and equipment.

Eliminating waste. JIT helps to reduce waste from overproduction, processing waste, transportation waste, inventory waste, product defects and waiting time. Automation is also an element of JIT that helps to reduce errors. Machines with more autonomous judgments can perform mundane and repetitive work so that humans can carry out more useful tasks. Worthwhile to mention, JIT increases flexibility and facilitates multi-skilled workforce which has higher productivity, flexibility and small margins of error.

Qualitative and Quantitative Forecasting Method

The quantitative forecasting is largely dependent on the ability of Apple’s forecasting team to make calculations that help the company to generate forecasts related to Apple’s effective supply chain management. On the other hand, qualitative forecasting relies on the ability of the firm’s forecasting team to make educated and sophisticated guesses. Makridakis et al. (2008) says that quantitative forecasting requires past data whereas qualitative forecasting relies on the ability of the forecasters to predict trends and extract meaningful insight from it.

Table 1. Qualitative and quantitative forecasting method

| Quantitative Forecasting Method | Quantitative Forecasting Method. |

| The sharing of work in the production line and its influence on the supply chain management. | Product growth in the market |

| The production process and its impact on the production process. | Customer desires and their trends. |

| The role played by existing technology in the product manufacturing process. | Market demands and tastes. |

Under quantitative forecasting, aspects such as the demand of the market, consumer purchasing behavior and the performance of the supply chain management can be assessed. On the flipside, qualitative forecasting is not very efficient because the market is usually volatile and therefore, no firm can accurately predict the future of marketing. This is because qualitative forecasting relies on data on customers about desires and purchasing potential which are subject to change. Quantitative forecasting, on the other hand, can be very useful in making informed judgments by taking advantage of previous data to predict future trends. However, qualitative forecasting can prove indispensable especially when done by experienced forecasters who have accrued market experience and can provide informed forecasts for their products.

Conclusion

Apple Inc. should consider integrating design thinking with user-led product solutions in their new product design and process selection. Apple Inc. to solve their supply chain problem should explore the possibility of diversifying its supplier base to cushion itself against the shortcomings of its suppliers. Also, it should leverage supplier technology to keep tabs on delivery performance, production and yield rates and compliance factors. Hence, the improvement in operation process with the help of Total Quality Management Tool and Just in Time (JIT) would help Apple to reduce the entire issues related to product life cycle and gain the huge market share with the aid of increase in products’ maturity.

References

Apple (n.d.). Reports - Supplier Responsibility. Retrieved January 18, 2017, from http://www.apple.com/supplier-responsibility/progress-report/

Arndt, H. (2004). Supply Chain Management. Gabler Verlag Springer Fachmedien Wiesbaden GmbH, Wiesbaden.

Berk, J. & Berk, S. (2000). Quality Management for the Technology Sector. USA: Butterworth- Heinemann.

Cheng, T. & Podolsky, S. (1996). Just-in-Time Manufacturing: An Introduction. Springer.

Makridakis, S., Wheelwright, S. C., & Hyndman, R. J. (2008). Forecasting methods and applications. John Wiley & Sons.

O'Grady, P. J. (Ed.). (2012). Putting the just-in-time philosophy into practice: a strategy for production managers. Springer Science & Business Media.