Supply Chain Management HW Case Study

Acme Apparel

Case: Acme Apparel Supply Chain Logistics DilemmaAcme Apparel is a $150 million manufacturer and distributor of basic apparel items such as underwear, panties and socks. Acme sells through mid-tier retail chains and is trying to break into the major “big box” retailers. It sells private label programs under its own label, and manufactures a small amount for other apparel suppliers.

The global market for apparel is extremely price-competitive, forcing suppliers into relentless efforts to drive down their costs. Among these efforts is global sourcing to take advantage of imports from low wage economies and regions, including Asia. Acme has struggled in recent years, and witnessed three years of declining profits due to price compression and difficulty reducing their cost structure. In response, the Board of Directors brought in new President Gerald Jeffs, with industry experience and an impressive turnaround background.

After reporting to work (once he was safely on board), the Board briefed Mr. Jeffs on the challenge before him. They explained the “rest of the story”. In addition to a high cost structure, Acme suffered from historically weak performance from its supply chain. Specifically, inventory turns were too low, manufacturing schedule and shipping performance averaged 80 – 90%, waste and off-quality were too high versus their benchmark group, and distribution and logistics costs were high at over 6% of revenue dollars. The new President would have to act quickly to resolve these problems and get the firm back on track to profitable growth.

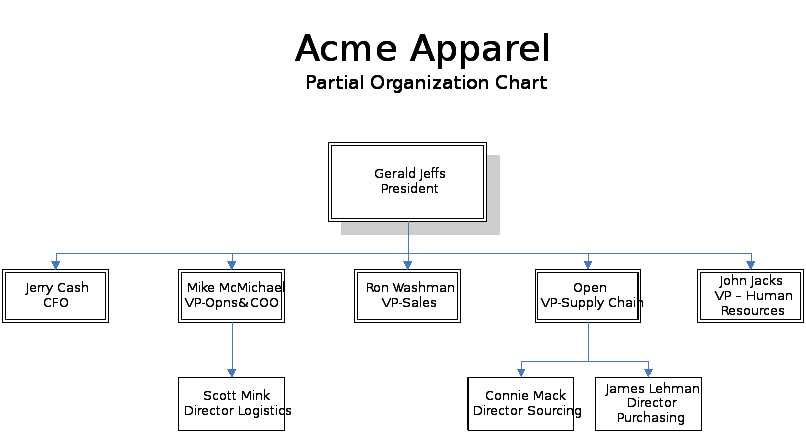

The First 90 DaysShortly after his arrival, Mr. Jeffs evaluated his new organization and decided to make 4 key hires (see Appendix):

VP of Sales, reporting directly to the President. Hired Ron Washman, a strong sales manager hired from a competitor with solid contacts in the retail industry.

Director of Logistics, reporting to COO. Hired Scott Mink, who had implemented strategic logistics transformation for a major office supply company.

Director of Sourcing, reporting to VP-Supply Chain. Hired Connie Mack, an industry veteran with an extensive global industry network.

Director of Purchasing, reporting to VP-Supply Chain. Hired James Lehman, who had a strong record leading and transforming global purchasing organizations.

Mr. Jeffs made sure each of his new hires was properly oriented and grounded in his new Supply Chain strategy, which he summarized into these key points:

- Sell more by penetrating key retailers with programs that Acme can support profitably and successfully, meeting retailer expectations and requirements.

- Reduce cost structure as quickly as possible to increase profit margins. Use global sourcing and global purchasing leverage to reduce the cost of supply.

- Increase customer service and on-time shipments through standardized global transportation and logistics processes. Also, use logistics excellence to reduce shipping costs, increase delivery reliability and hold supply plants (owned and sourced) accountable for meeting on-time production and shipping schedules.

All of the new hires were integrated quickly into the company and began the work of reviving their respective functions. Ron Washman reorganized the sales group along a key account focus, to drive his reps to work at breaking into the major retail accounts. Ron traveled heavily, meeting with customer senior management and assessing which relationships were solid and which needed work. He identified and brought back several promising retail program opportunities, but was concerned about the supply chain’s ability to deliver. He knew Acme must demonstrate near-flawless performance on these initial programs, or there would be no second chance.

In Sourcing, Connie Mack quickly identified some programs which were internally manufactured at low profit margins that could be sourced at lower cost. She began working with the VP-Operations and Purchasing to convert these programs from “make” to “buy”. The company had little experience importing from Asia, but Connie put basic processes in place, training her staff while developing the necessary business processes.

In Purchasing, James began a departmental “transformation”. He reorganized his department along a category management structure. He implemented “crash” training for his staff on the basics of category management and procurement excellence. He met with senior management from key suppliers to evaluate and strengthen these relationships. To supplement Acme’s legacy in-house ERP system, he acquired new applications for Spend Management and E-Procurement. He was frustrated with difficulty in “proving” the resulting cost savings through Acme’s aging financial application systems, but was beginning to show progress.

In Logistics, Scott Mink quickly determined that he needed to rationalize his transportation network around one or at most two global logistics providers, or “GLP”s. After an RFx process run by Purchasing, he decided to award the business to AB Global Logistics, and began converting all Acme shipments to use ABGL booking and transportation. This had two major benefits – the lower rates AB quoted (based on consolidating all of Acme’s transportation volume), and the use of AB’s information visibility solution, “Global Eye”. For the first time, Acme had visibility to all its global shipments through a central database and powerful reporting provided by the “Eye”.

The DilemmaSizing up progress during his first year in the job, Mr. Jeffs felt confident that things were moving in the right direction, until he read his email, which included the following:

Date: June 22. 2007

TO: Gerald Jeffs

From: James Lehman

Subject: Master Supplier Contracts

Gerald, as an update, we are making progress on the rewrite of the master supplier contracts that we discussed last month. A draft agreement has been reviewed by Legal, and we are preparing to implement it at the Supplier Conference we’re planning for next quarter. This will get us on common terms and conditions with all suppliers, and provide consistent “rules of engagement” to help manage any potential disputes that may emerge. This proved critical in my last company, and I am confident it will protect us in the same way.

Date: June 24. 2007

TO: James Lehman

From: Scott Mink

Cc: Gerald Jeffs

Subject: Master Supplier Contracts

James, I just finished reading your new master agreement. Overall it looks good, except for one big issue. You included language requiring that suppliers be capable of supplying product to Acme on a DDP basis from any global location.

You are familiar with all the work my organization has invested in our new global logistics network. If suppliers are required to ship DDP, they control the transportation and delivery to the destination port, including clearing customs. This will circumvent our global network – probably at higher cost. If they are shipping LCL, we lose any consolidation opportunities. Finally, we lose visibility of the inbound shipment, which will not show up in the “Eye” reporting. We need to remove this provision from the master agreement. Keeping suppliers on FOB terms ensures that we control the inbound logistics for purchased materials, not the suppliers. For us, control means low cost and inventory visibility, both of which are key to our strategy.

Date: June 24. 2007

TO: Scott Mink

From: James Lehman

Cc: Gerald Jeffs

Subject: Master Supplier Contracts

Scott, I read your email and I am concerned. We seem to have an alignment problem. My direction is to ensure the lowest possible cost of supply from our global supplier network. In order to do that, I need to develop our supply base, including the capability to deliver their materials into the domestic transportation network at their expense. As a bonus, they get the burden of clearing customs, further saving Acme that expense and trouble. DDP terms reduce our workload, cost and responsibility, which is exactly what Gerald hired me to do.

Date: June 26. 2007

TO: James Lehman

From: Scott Mink

Cc: Gerald Jeffs

Subject: Master Supplier Contracts

James, I think you have the alignment problem. Gerald hired me to reduce logistics cost. DDP supplier terms will undo all the work we have done to build a global logistics network, and raise cost too. Have you done a total cost of ownership (TCO) analysis on DDP vs. FOB terms? Where is the lowest total cost?

I think we need to take this to Gerald. I am sure he’ll understand my position.

Date: June 27. 2007

TO: Scott Mink

From: James Lehman

Cc: Gerald Jeffs

Subject: Master Supplier Contracts

The end state is for procurement to provide a VMI solution to the manufacturing operations to support the Lean pull-initiatives.

To support the above, all key suppliers (who have the volumes to ship full container loads) must have the ability to ship in-country and own the inventory.

It’s a step-wise approach that we get the suppliers to develop the capabilities to ship in region (CIF to port of entry) and then to country (DDP).

If the above is accomplished, then the supplier would take ownership of the components instead of Acme during transit and buffer inventory.

1-2 weeks transportation (China -> SE Asia)

2-3 weeks of buffer inventory at our plants

The above translates into 4-5 weeks of inventory off of Acme books.

If we are currently turning 2.6, that’s about 20 weeks of inventory. If we can take 4-5 weeks out, that’s a 25% improvement on turns.

This is not a one-size fits all solution and it’s more than just cost of the transportation. This is about supporting the supply chain objectives. I’m surprised to find that there are still comments made about purchasing simply looking at the component costs.

There will be two scenarios to consider: 1) loose components that cannot fill a full size container which will require consolidation and 2) regular shipments that will fill a container which we can move to VMI system much quicker.

Until we can figure out how to price mask the deals with the 3P logistics providers, we need to balance and get our suppliers up to capability.

Pondering this exchange, Mr. Jeffs realized he needed some background on some of the issues and terms contained in the emails. Then, he needed to provide clear leadership and resolution of this issue to these two key managers.

- Give a complete synopsis of the case. Consider these terms and issues for your background discussion:

- Incoterms: DDP, CIF, FOB etc.

- TCO (Total Cost of Ownership)

- LCL (Less than Container Load), FCL (Full Container Load)

- Port of Entry (Duties/Tariffs, Infrastructure, transportation available)

- Free Trade Zones (FTZ)

- Consolidation / Deconsolidation

- GLP (Global Logistics Providers)

- Global logistics visibility

- Logistic Cost Trade Offs

- Supply Chain Risks

- Vendor Managed Inventory (VMI)

- In your opinion, who has the stronger fundamental argument: Mr. Mink or Mr. Lehman? Make sure to substantiate your answer with consideration of the issues/terms in Question 1.

- How could each executive prove his strategy was the best for the organization?

- Are there any organizational changes that Mr. Jeffs should consider? Please spell out in detail in your opinion what Mr. Jeffs should and how should he implement his actions.

- What specific direction should Mr. Jeffs provide to Scott and James?

Sales $152

Average Inventory $58

FG $43

WIP $6

RM $9

Cost of Sales $122

SG&A $22

Earnings (Gross) $30

Earnings (Net) $8

9