logistics topic: Solving one issue in Intel company case study (need only 2 pages )

WAREHOUSING STRATEGY AT INTEL CORPORATION

Stuart Love, Jeff Macias and Josh Cork wrote this case under the supervision of Professor James Kellso solely to provide material for class discussion at Arizona State University. Case revisions have also been made by James Zamora and Alexander Spicker. The authors do not intend to illustrate either effective or ineffective handling of a Supply Chain Management situation. The authors may have disguised certain names and other information to protect confidentiality and intellectual property.

Copyright © 2017, Intel Corporation

INTRODUCTION

It was Monday, September 22nd, 2014, and Jack Tyler, the Director of Warehousing and Logistics at Intel Chandler, (which was also internally known as J76) was reviewing the latest report provided by the floor supervisor of Shift 3 Denise Martin. In the report, it had been noted that demand for end product had increased by 85% over the normalized seasonal demand. This was a change from the previous month, where overall demand had been equal to the prior month. Furthermore, overall demand year over year had been down by 10%. In this case, demand is driving both customer sales and also factory production from an inbound materials perspective. Due to the report, the floor supervisor expressed concerns that he did not have enough human resources to adjust to this recent increase in demand. Nine months prior, the warehouse converted to a new order processing system that changed the way orders were pulled, packed, labeled and shipped, which complicated the issue. However, customer representatives have been alerting Mr. Tyler of a significant increase in customer complaints due to incorrect content, or damaged boxes and misplaced labels, which had increased problems with customer’s inventory handling systems. This feedback was now reaching the top levels of management, as many of these customers were significant contributors to Intel’s revenue and more importantly key partners in strategic initiatives in the market.

Mr. Tyler felt that the recent introduction of a new product line was potentially creating significant demand variability and this scenario needed to be assessed. He had already heard concerns from David Goodwin, the commodity Manager for J76 that the warehouse was unable to meet some customer requirements of getting the correct product to customers on time with the correct quality desired, and it was thought some system issues were the root cause. There had been some system corrections, which were implemented recently. However, he wasn’t sure if the system was continuing to contribute to the most recent complaints. Ms. Martin was not aware of this conversation. Mr. Tyler had scheduled a meeting with Ms. Martin, Mr. Tyler and the other members of the warehouse team Tuesday to work on a plan to identify root cause and correct all of the issues. A decision was critical to resolve these issues as J76 processed orders all over the world and Mr. Tyler had to have a strategy and execution plan in place for his report out to the Executive Vice President of the Technology and Manufacturing Group on November 25th.

Intel Warehouse J76

J76 is a global Intel warehouse located in Chandler Arizona and is responsible for a range of key finished good products to numerous customers. J76 customers concern themselves with excess inventory and they want shipments delivered on time (not late or early). This warehouse processes thousands of orders per week. In general, J76 had historically expected increases in year-over-year sales volume and normal seasonality. The products in J76 range extended from low-consumption, small-embedded devices to the most cutting-edge mobile technology. J76 is one of many strategically located warehouses within the Intel network.

While ensuring that customer fulfillment is met, there is tension on the supply chain as any factory downtime is very expensive and has been calculated at $1,000,000 per day if the factory is shut down. Currently, raw materials consume 50% of the space and finished goods consume 25% of the space at J76. Maintenance Repair Operation (MRO) consumes 25%. A further breakdown of the supply chain costs can be seen in Appendix A.

J76 is a 160,000-square-foot facility that was 400 feet in length and 400 feet in width with a 30-foot ceiling. The warehouse is fixed in size, and Intel is not currently allocating capital investments to increase capacity.

Warehouse Management System

The new warehousing system called IOE (Inbound and Outbound Excellence) is an out-of-the-box ERP system, which was implemented in 2013. The system manages the way orders are pulled, and gives warehouse operators instructions on how to box and pack. IOE also generates automated labels and gives instructions where the finished goods are to be shipped. This system connects directly with Intel’s ERP system SAP, which manages customer ordering as well as financial and accounting information. The system had a cost of $1.6 million to implement and the project required two years to implement. Ms. Martin herself received significant recognition for the system implementation and was a strong advocate for the system’s benefits. However, recent issues have been creating customer dissatisfaction as indicated in the introduction.

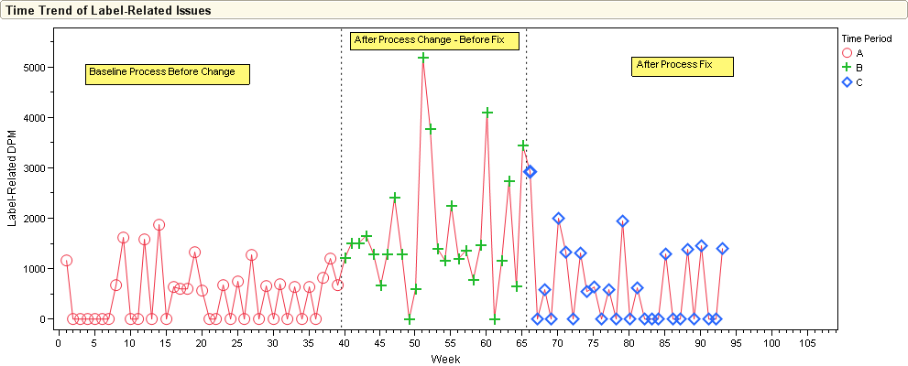

Ms. Martin identified that printer drivers and hardware were not compatible with IOE. There were also incorrect time zones configured into the new system (PST as opposed to MST). Another large problem was that often incorrect master data was entered into the system – actual weights for the products were causing incorrect data on the labels and documentation required for customs, which caused delays, especially for international customers. Appendix B shows the number of labeling issues for various time periods of the process. Appendix C shows a list of issues compiled by Ms. Martin from quality engineers. There have been some additional discussions between Ms. Martin and Mr. Goodwin, where Mr. Goodwin felt IOE was a real problem in terms of causing customer issues, while Ms. Martin felt the appropriate fixes had been put into place. This has caused some interpersonal friction, and this friction has grown more as demand for finished goods has become more variable.

Intel’s Value Chain

Intel’s Value Chain begins with the customer. Customer excellence is a key component of Intel’s business model and also a major factor in compensation, via bonuses. This can be a significant portion of compensation for senior Intel employees, and all employees receive bonus compensation to keep alignment of goals. “We sell our products primarily to OEMs (original equipment manufacturers) and ODMs (original design manufacturers). ODMs provide design and/or manufacturing services to branded and unbranded private-label resellers. In addition, we sell our products to other manufacturers, including makers of a wide range of industrial and communications equipment. Our customers also include those who buy PC components and our other products through distributor, reseller, retail, and OEM channels throughout the world1.” However, it is important to note that operational goals such as balancing inbound and outbound costs are also included in these bonuses. J76 needs to balance customer excellence and the value it provides to Intel from an operational perspective.

Inbound Sourcing and Procurement

Activities in the J76 warehouse scope include receiving materials, issuing parts to the factory, processing returns, and cycle counting. This includes both Raw Materials and MRO items (maintenance, repair, other) to support the local factory as well as shipping finished goods to support customer orders. Currently labor is split between receiving, issues/returns, and shipping. Additionally, warehouse capacity is broken out by material type (A breakdown of these supply chain costs can be seen in Appendix A.). All of the above activities are critical to factory uptime and cannot be overlooked (recall the aforementioned cost of factory downtime). Mr. Goodwin has also been monitoring the overall transit time to ensure customers are receiving finished goods on their target date (See Appendix C). Mr. Tyler and Mr. Goodwin have in the past considered reallocating warehousing capacity and labor as a potential solution to some of their issues, but have often been in disagreement on whether space should be allocated. Mr. Tyler felt that reallocation could help ensure customers were being supported from demand upticks if the space was correctly redesigned. However, Mr. Goodwin was adamant that raw materials needed at least 50% of the warehouses capacity to ensure the factory was properly staged to execute to its schedules.

Intel

Intel Corporation is located in Santa Clara California with $55.9 billion in revenues2. While resources vary across the corporation, the current environment for J76 is that all headcount is flat, which means Mr. Tyler must justify any hiring increases directly with the Vice President. Attrition is assumed to be 3.0% and backfill for those resources must also be justified as business critical. Since the cost for the IOE system was so high, and the fact that it took two years to implement, it is unlikely that Mr. Tyler would receive additional funding to replace the system. Mr. Tyler knew that an easy solution would be adding human resources to meet increasing demand. However, he felt that under the current pressure to keep operating costs down, it would be a difficult value proposition to justify the additional human resources to solve the problems.

The Decision

Later in the day Mr. Tyler got off the phone with a critical customer who was not happy with the recent shipment quality and threatened to switch to a competitor if the problems were not resolved. As a starting point for the meeting on Tuesday, Mr. Tyler needs his team to come up with a root cause of the issues immediately. He needs his team to understand the magnitude of the issue form a strategy and execution plan and make recommendations for his meeting with the V.P.

Appendix: The data contained in this exercise is not the actual data from Intel, but is randomly generated

Appendix A: Supply Chain Costs

Appendix B: Labeling Issues Over Time

Source: Intel MSU Case Study 2013

Appendix C: Transit Time for Finished Goods Products

Source: Intel MSU Case Study 2013

Appendix D: Other Issues Compiled by Intel

Outdated printer drivers and hardware not compatible with most of the new system

Wrong time zones configured in the new system (PST, vs. MST or GMT)

Wrong master data for products in the system – incorrect actual or dimensional weights for the products causing net weight issues on the labels and documentation for customs, causing delay at customs

Inconsistent unit count on labels vs. advanced shipment notification sent to the customer

Missing advanced shipment notification for raw materials coming into the dock – not knowing what to receive against

Appendix E: Intel J76 Warehouse & Factory

1 Intel 10-K 2-19-15

2 Intel 10-K 2-19-15