Help with a team project related to operation management

Bombardier Inc’s problems go far beyond planes: How a failure to deliver streetcars on time has ripple effects across Canada

Peter Kuitenbrouwer | May 9, 2016 10:41 AM ET

More from Peter Kuitenbrouwer | @pkuitenbrouwer

http://business.financialpost.com/news/transportation/bombardier-incs-problems-go-far-beyond-planes-how-a-failure-to-deliver-streetcars-on-time-has-ripple-effects-across-canada

Edmonton Transit’s Quinn Nicholson recently toured a few excavation projects under a main east-west artery in Toronto where a 19-kilometre light rail train will eventually run beginning in 2021. But one thing was missing from the spokesman’s tour of this $5.3-billion project, the largest transit expansion in Toronto’s history: the train.

Bombardier Inc. had agreed to deliver the prototype five-segment light rail vehicle for this line under Eglinton Ave. 18 months ago. Toronto is still waiting.

These delays hit home for Nicholson, since Edmonton recently inked a deal with Bombardier to deliver the trains for its Valley Line, which broke ground last month with a target to open in 2020. “Obviously, the citizens of Edmonton have been watching the situation in Ontario with some trepidation,” he said.

They have reason to worry. The delay in Toronto is just one part of a huge production snafu for Montreal-based Bombardier, which blames supply chain issues for epic delays in delivering vehicles from its plant in Thunder Bay, Ont. Those problems appear set to ripple across the country. Altogether, six rapid transit systems across Canada have ordered trains from troubled Bombardier Transportation.

Bombardier is trying to straighten things out. In December, the company replaced Lutz Bertling, global president of its trains division, with Laurent Troger, and last month replaced its transportation president for the Americas, Raymond Bachant, with Benoît Brossoit. Bombardier now says it will enlist two additional factories to increase the speed of light rail train production for Canada.

“Every manufacturer encounters some issues,” said Marc-André Lefebvre, a spokesman for Bombardier. “We have had more than our share of issues. But what distinguishes us is that we will stand by our customers until the end.”

The customers, though, are growing very tired of all the excuses, apologies and failed promises.

“We have concerns about quality,” said Anne Marie Aikins, a spokeswoman for Metrolinx, the Ontario agency building the new line, “and we are not getting reassuring statements about how they are going to get it done to our standards and to our deadline.”

The Toronto Transit Commission has ordered 204 low-floor streetcars for $1.2 billion, due by 2019. Metrolinx has spent $770 million for 182 trains, due in the next five years, which will run on two streets in Toronto as well as in Brampton, Mississauga and Hamilton. The Region of Waterloo has also ordered 14 trains for its $818-million ION line linking Kitchener to Waterloo.

The region of Waterloo said its 2013 vote to buy trains through the Metrolinx-Bombardier deal would represent “a decrease in project schedule risks.”

Today, none of Bombardier’s Canadian light rail clients sound happy,

“Bombardier is on to its seventh project manager in Thunder Bay,” says Andy Byford, chief executive of the Toronto Transit Commission, which has received 18 new streetcars of 75 Bombardier had promised by this point. “Bombardier has just changed their president (for the Americas). I met the new guy (Brossoit). I was impressed with him.” Still, he adds, “this is intensely frustrating. It’s breaking my heart.”

The troubles today belie the fact that the railway plant in Thunder Bay has reliably turned out trains for more than a century. Born as Canadian Car and Foundry in 1902, the plant about 30 years ago produced 250 streetcars that currently operate in Toronto.

Bombardier bought the plant in 1992 and it is now completing an order of 480 subway cars for Toronto without major issues; Bombardier is also building 64 bi-level commuter train cars for Ontario’s GO Transit. “They are coming gradually, on schedule,” Aikins said.

But building the “Flexity” light rail vehicles for Toronto’s new line has proved far more challenging. These trams — which Bombardier has built for Belgium, Sweden, Norway and Germany, but is only now bringing to North America — are complex machines: they are low-floor (with mechanical systems on their roofs), air-conditioned and come loaded with electronics: Bombardier even replaced the bell on the old streetcar with an electronic sound that simulates a bell.

To complicate matters further, the streetcars Bombardier is building for Toronto have a different wheel gauge than the trains for Metrolinx, and need to navigate tighter curves.

To save money, Bombardier decided to build frames, floors, bogies (wheel assemblies) and wiring harnesses for the streetcars at the plant it bought years ago from the Mexican government in Ciudad Sahagun, not far from Mexico City.

But when the Mexican-made parts arrived by truck 4,000 kilometres north in Thunder Bay, workers discovered that they did not fit properly together.

“The parts were not of a quality where we could stick them on the car,” said Dominic Pasqualino, president of Unifor Local 1075, which represents 920 workers in Thunder Bay, and who is a third-generation employee of the plant. “We spend so much time reworking or waiting for parts, and the lines get shut down, and it’s so frustrating.”

The plant works more efficiently when it builds cars in-house, he said. “Now we’re translating into two languages and going across two borders. These are complicated cars, and there’s a lot of revisions when you are making a brand-new car.”

Production is hopelessly backed up now.

“There’s a huge warehouse at the Keifer terminal in Thunder Bay and it’s full of parts,” Pasqualino said. “I know what our reputation is now in Toronto. We are being mocked on the Rick Mercer Report. What has this done to the company brand and reputation?”

Byford said that when Bombardier tried to use up some of this parts backlog, “they discovered the parts didn’t fit.”

The TTC and Metrolinx had only required 25-per-cent Canadian content on their vehicle orders. Allowing providers to source parts offshore may have saved the purchasers some cash, but it may also have caused some of the delays.

By contrast to the Ontario problems, Bombardier has had somewhat better results at its plant in La Pocatière, Que., about 150 kilometres northeast of Quebec City. That plant, which has built subway cars for New York and Boston, is currently building 468 metro cars for Montreal in a $1.2-billion untendered joint Bombardier-Alstom contract from the province of Quebec.

To comply with a 60-per-cent Canadian content rule for the metro job, Alstom in 2013 built a factory in Sorel near Montreal to build the wheel assemblies. Still, the consortium ran late. It had agreed to deliver to Montreal the prototype “Azur” train in July 2013, but only sent it in April 2014.

“The delivery delays were due to the train control systems,” said Amélie Régis at the Sociéte de Transport de Montréal. “The Bombardier-Alstom consortium promises that they can speed the production schedule to deliver them by 2018.”

Bombardier has now announced it will build streetcar underframes and cabs for the Toronto subways in La Pocatière and send them to Thunder Bay for assembly, which is good news in the eyes of Pasqualino in Thunder Bay.

“The walls and roofs for the Toronto subways are built in the La Poc plant,” he said. “Parts from La Poc are no problem.”

Lefebvre at Bombardier said the company will also add a fourth assembly plant for the light rail job.

“We are looking at Canadian and worldwide plants to find the best plant with the most resources to get cars out as soon as possible,” he said. “We will be communicating our plan to Toronto in the next few weeks.”

In the meantime, Bombardier, whose slogan is, “Looking far ahead while delivering today,” and which boasts that “about 5,000 Bombardier trams and LRVs are in revenue service or on order in Europe, Asia, Australia and North America,” has had to eat a fair helping of humble pie over the Canadian light rail mess.

Lefebvre, who has apologized repeatedly to the company’s light rail customers, said, “We are not looking at short-term objectives. With new leadership comes new ideas and new perspectives. Benoît Brossoit has a background in large-scale manufacturing operations. We are adding capacity, with sub-assembly component built in Mexico and La Pocatière.”

Back in Edmonton, Nicholson said the private-public structure of the Valley Line deal insulates the city from the kind of delays currently punishing Toronto transit riders. Edmonton has signed a 35-year deal for a consortium made up of Bombardier, Bechtel Corp., EllisDon Corp. and Fengate Capital Management Ltd. to design, build, operate and maintain the 13-kilometre line for 35 years.

“The beauty of the P3 model is that the other partners hold them accountable,” he said. “If it reaches a situation where they aren’t able to deliver, the city of Edmonton will be the least of Bombardier’s problems. The other partners could simply swap out a different train provider. We feel it will work out.”

Financial Post

Bombardier’s Thunder Bay plant hit with supply chain woes

Peter Kuitenbrouwer | January 5, 2015 | Last Updated: Jan 5 9:13 AM ET

More from Peter Kuitenbrouwer | @pkuitenbrouwer

http://business.financialpost.com/news/transportation/bombardiers-thunder-bay-plant-hit-with-supply-chain-woes

THUNDER BAY – The Bombardier plant here, which sprawls on the Kaministiquia River near the city’s airport, is so big that the company maintains a fleet of 100 adult tricycles, which workers pedal through the endless corridors of the facility to deliver parts, tools and paint.

The 102-year-old factory — founded as Can Car, or Canadian Car and Foundry — has a storied history. In its first decade, it received orders for 9,000 rail boxcars, along with a dozen minesweepers for the French navy. In the Second World War, the plant built 1,451 Hawker Hurricane fighter airplanes for the RAF and the RCAF; its workforce peaked at about 7,000, including 3,000 women. In the 1970s and 1980s, the plant built the streetcars that ply Toronto’s streets, along with over 1,000 double-decker commuter rail cars for GO Transit, the Agence métropolitaine de transport in Montreal, and 14 U.S. transit systems, including services in California, Utah, New Mexico and Florida. Bombardier Inc. bought the plant in 1992.

The factory secured its future when it won orders in 2007 for 480 subway cars for Toronto. Then in 2009 Toronto ordered 204 low-floor, air-conditioned light rail vehicles — also known as streetcars — from Bombardier for $1.2 billion, for delivery by 2018.

On a visit to the Thunder Bay plant early in December, about 875 workers were toiling on the lines, turning out about two subway cars a week, and assembling rail cars and streetcars. Another 250 people worked in the offices. But the tour guides seemed oddly skittish. When a reporter stopped to interview a worker in the “marrying station,” where workers put the parts of the vehicle together, project director Bill Williams told the reporter, “Please make it quick. They are on the clock right now and they are working.”

All is not well at this facility. Bombardier did not disclose it to a visitor, but the company is laying off 49 people here in December and January. Upon later inquiry, the company confirmed that it cannot keep these workers busy because of challenges getting parts to the plant from the Bombardier factory in Ciudad Sahagun, near Mexico City, among other places.

Problems have badly delayed the shipment of streetcars to Toronto. Six years after placing an order, Toronto says it should have 43 low-floor streetcars by this point. Instead, it has just three in service.

“The delivery is far behind from the original schedule,” says Brad Ross, a spokesperson for the Toronto Transit Commission. “We are still working with them on meeting their original schedule. If not, there will be liquidated damages and the like.”

Mr. Ross learned from the Financial Post that Bombardier was planning to lay off workers on its streetcar assembly line. “I had no idea,” he said. “Interesting. That’s news to me.”

Bombardier blames the delay in building the streetcars on Toronto’s unique streetcar track gauge; on a nine-week strike here last summer; on problems designing a ramp to load disabled passengers; and on managing inventory of parts.

But workers say the problem stems from Bombardier’s approach to the streetcar job. For subways and two-level trains, Bombardier built the modules in Thunder Bay. For the streetcar, though, Bombardier chose to source parts globally. The gear box comes from Germany, the motor from Germany, the brake systems from the U.S. and France. Bombardier makes the car structure modules in its plant in Sahagun, and ships them here by flatbed truck.

“We have a worldwide assembly chain,” says Mr. Williams. “This is a European product that we have North Americanized.”

The workers in Thunder Bay “stuff it, splice it, glue it, bond it, build a car and test it,” says Peter Koukos, director of operations, pointing to a spaghetti-style tangle of exposed wire in a streetcar module.

Such a global supply chain poses challenges when pieces don’t come, come late, or do not fit.

The layoffs are, “in part, because of issues with some of our suppliers,” said Marc-André Lefebvre, a spokesman for Bombardier in Montreal. “We do have issues making sure that our line is working in the most efficient manner.”

Mr. Williams said, “We are ramping up production right now.” But Unifor spokesman Andy Savela in Thunder Bay said Bombardier is sending workers home because they don’t have the pieces they need. Streetcar bodies and frames made in Bombardier’s plant in Mexico are either built to the wrong sizes or are defective, according to Mr. Savela and another source in the plant.

“We did an amazing amount of work in-house for the bi-level car,” says Mr. Savela. “Our big thing is, we are encouraging them to pull more work back in-house to avoid these problems. Through no fault of their own, 50 of our workers got layoff notices right before the holiday season.”

Asks another worker, “Is it really a cost savings if you are building the parts and we can’t use them? We are stuck with all these parts built on an angle that is not right. We’re highly frustrated. The big fear is that it puts the plant in a bad light when it has nothing to do with us.”

Mr. Lefebvre calls workers “short-sighted” when they blame one facility for the problems. “There are challenges all over, so it is not specific to any one site,” he says. All of Bombardier’s plants are integrated, he says. “Thunder Bay ships parts to La Pocatière, Quebec, it ships parts to Plattsburg. Parts are going back and forth.”

Mr. Williams seeks to put the best light on the situation.

“It’s challenging to get everything started up,” he says. “We are negotiating with the TTC. We are discussing and working with them. We have a very dedicated team. They are very focused, very dedicated, very proud. That goes back to the generations who have worked here.”

While Toronto says its deal promises delivery by 2018, Mr. Williams says, “the schedule is until 2020.”

Says Mr. Lefebvre, “We will do our utmost to make sure we go as fast as possible.”

Commuters accustomed to waiting for transit vehicles have heard this line before.

Toronto Life

A timeline of Bombardier’s excuses for not building Toronto’s new transit fleet

By Steve Kupferman | January 5, 2017 AT 2:44 pm

http://torontolife.com/city/transportation/timeline-bombardiers-excuses-not-building-torontos-new-transit-fleet/

For the past decade, the Montreal-based vehicle manufacturer Bombardier has held a surprising amount of sway over the future of public transportation in Toronto. If it rides on rails, Bombardier is making it: the company has contracts to build the city’s new streetcars and subway trains, and it’s also putting together the light-rail vehicles that will run on the Eglinton Crosstown.

In retrospect, it turns out awarding all this vital work to a single manufacturer may not have been such a great idea. Although Bombardier recently announced, triumphantly, that it has met its latest delivery deadlines, Toronto’s streetcar order remains badly behind schedule (the TTC has received only 30 of the 204 new vehicles) and Metrolinx’s light-rail vehicle order appears to be in deep trouble. Every few months, it seems, there’s a new reason for the tardiness. Here, a timeline of Bombardier’s excuses.

July 2008: A fatal flawAfter a lengthy bidding process, Bombardier had emerged as the likely winner of a contract to build the TTC’s next-generation streetcar fleet. A slight problem soon emerged: on closer study, the TTC decided that Bombardier’s proposed streetcar design, as well as the designs of two other companies who were bidding on the contract, would likely derail on tight curves. After some design tweaks, Bombardier got the contract anyway.

April 2010: A bankruptcyAlready delayed, Toronto’s next-generation subway train rollout suffered a further setback when Bombardier informed the TTC that it wouldn’t be able to deliver the first of the new cars for a few more months because of theNew York–based company that was supposed to be manufacturing the sliding doors had gone bankrupt.

January 2015: MexicoThe National Post reported that Bombardier was laying off workers at its Thunder Bay assembly plant, in part because of problems importing streetcar parts from its factories around the world—particularly its plant near Mexico City. Even when the parts did arrive, they sometimes didn’t fit correctly.

May 2015: Still MexicoMetrolinx told the press that Bombardier’s problems with its Mexican plant were also delaying the construction of vehicles for the Eglinton Crosstown. “Yes, we have in this case had issues in Thunder Bay, and we have had issues in Mexico,” a Bombardier spokesperson told the Star. “We were working on correcting them. Now they are corrected.”

June 2015: Or, mismanagement?When TTC chair Josh Colle visited Bombardier’s Thunder Bay plant to check on the city’s backlogged streetcar order, he returned full of confidence, in part because Bombardier’s leadership had told him that some of the senior managers in charge of the production line had been replaced.

October 2015: Mexico, againStreetcar delays were so pervasive that the TTC had begun to consider legal action. Bombardier again blamed the production delays on its Mexican workers. This time, apparently, the south-of-the-border factory was crimping electrical connectors improperly.

September 2016: Who knows?After missing another Metrolinx deadline, Bombardier didn’t bother with an excuse. A spokesperson told the Star that the company hoped to “accelerate the inspection process” in order to speed up delivery of the first Eglinton Crosstown vehicle.

January 2017: A new hopeAlthough Bombardier hasn’t delivered any streetcars since December, TTC spokesperson Brad Ross says the commission is expecting 40 of the new vehicles this year. “The TTC will continue to hold Bombardier to account and meet its 2019 target for all 204 cars,” Ross wrote in an email. “Bombardier remain confident that they will meet that commitment.”

ClarificationJanuary 6, 2017

This post has been edited to clarify that Bombardier was not the only manufacturer whose streetcar design the TTC deemed likely to derail on tight curves.

CBCnews – Toronto

Mechanical problems surfacing in new streetcars more often than expected: report TTC says it's not concerned about the 'failures,' calls mechanical problems 'growing pains'By Muriel Draaisma, CBC News Posted: Jan 15, 2017 2:05 PM ET Last Updated: Jan 16, 2017 12:28 PM ET

http://www.cbc.ca/news/canada/toronto/report-new-ttc-streetcars-1.3936799

Thirty new streetcars on the road in Toronto are experiencing mechanical problems more often than expected, says a staff report to be presented to the Toronto Transit Commission board this week.

The TTC, however, said on the weekend that the "failures" are not of concern yet, not undermining rider safety and not a sign that the new streetcars from Bombardier are unreliable vehicles.

Brad Ross, spokesperson for the TTC, said the problems are "growing pains". The TTC tracks overall performance every month in its chief executive officer's report. The January 2017 report will be considered by the TTC board on Wednesday.

'TTC customers have been patient enough,' John Tory tells Bombardier

"With any new vehicle like the streetcar, there are going to be growing pains," Ross said. "There are going to be teething issues. And the issues we are seeing are very minor."

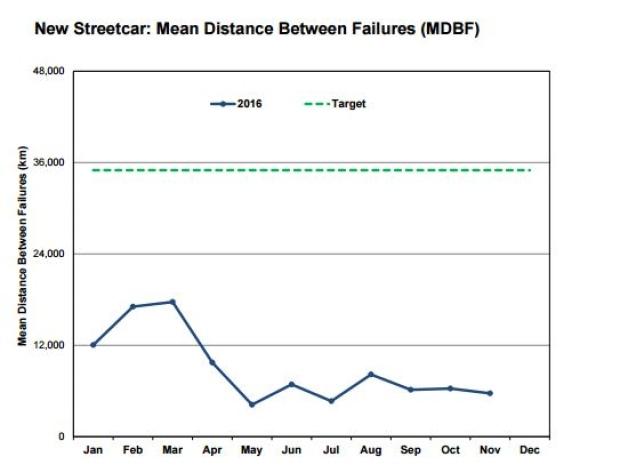

According to the report, "failures" were reported every 5,696 kilometres that they in service November 2016. The target distance between "failures" for the new streetcars is 35,000 kilometres.

Mechanical problems include doors that didn't open properly, brake issues of some kind, and intercom systems that didn't work.

The problems are plotted in a graph entitled, "Mean Distance Between Failures," which means the distance travelled before a mechanical problem occurs and is fixed.

TTC's staff report for January 2017 contains this graph that shows 'mean distance between failures' for its new streetcars. That means the distance travelled before the new streetcars on the road experience mechanical problems. (TTC Chief Executive Officer's Report January 2017)

"It's like a breaking-in period," Ross said. "For a complicated vehicle like a new streetcar, there are going to be issues."

When the TTC has 60 new streetcars in service, then the statistics will matter, he said. He predicted by then many of the mechanical problems will have been fixed and the distance between "failures" will be greater.

"The statistic in the report is not one that really concerns us because we only have 30 cars. We actually will need to have 60 of the new streetcars before any sort of failures become a concern for us."

Next new streetcar due to arrive this weekThe next new streetcar is scheduled to be delivered by Bombardier this week. Forty new ones in all are expected this year.

The report says: "As the TTC awaits the delivery of more new low-floor streetcars from Bombardier, this key performance indicator will become increasingly relevant. With so few of the new streetcars in service today, the performance indicator does not yet truly reflect just how well the new streetcars are performing.

"Even a low number of defects can have a significant impact on the mean distance between failures. The target of 35,000 mean kilometres between failures is expected to be attained on a regular basis as the sixtieth new streetcar is received."

But Ross said the TTC is tracking the problems because it needs to know how the vehicles are performing when on the road and in service, even though they are still under warranty.

"Because it's a brand new vehicle, we need to make sure that there isn't a systematic problem with the fleet," he said.

"Is this something that the manufacturer needs to go back and tweak and repair, at the production stage? Or is this something that is a one-off for reasons that are explainable or not explainable, depending on what the issue is?"

Ross said the new streetcars have to travel 600 kilometres "trouble-free" before they are actually put into service. And once in service, problems are tracked. During peak service, the TTC has 23 new streetcars in service on 510 Spadina, 514 Cherry and 509 Harbourfront lines. Seven are kept back for training and routine maintenance.

"We had this with the new subway trains, and now, they're great trains."

The TTC expects to have 70 of the Bombardier built streetcars by the end of this year and to have all 204 by end of 2019.

SpacingTTORONTO

LORINC: Bombardier’s Mexico problemMay 3, 2016 | By John Lorinc

http://spacing.ca/toronto/2016/05/03/bombardiers-mexico-problem/

According to the latest pronouncements from company executives, the epic shemozzle that is the TTC’s Bombardier streetcar contract — for 204 low-floor vehicles, at a cost of $993 million — will, henceforth, be dealt with in a hard-headed, business-like manner as befits a blue chip multi-national. Heads have rolled, blame has been apportioned, and attention is now focused, laser-like, on a real, honest-to-god, cross-my-heart-and-hope-to-die deadline: 2019.

Bombardier’s explanation for the fiasco is that components for the so-called Flexity vehicle, made on a sub-assembly line in a giant factory in Sahagun, Mexico, were inadequate, and thus held up the manufacturing process in Thunder Bay. But, as TTC CEO Andy Byford has noted, the company is also talking about “adding capacity” as a means of catching up on all those back orders.

If you think about it, those two explanations don’t exactly align. Indeed, I feel that plenty of skepticism about Excuse A — subpar components — is warranted as we try to figure out what the hell went wrong. After all, this wasn’t ever a case of measuring twice/cutting once.

Bombardier is a highly integrated manufacturer and it operates — as do all multi-nationals — with a network of global supply chains that connect its far-flung operations to one another and hundreds of sub-contractors. According to Bombardier itself, the Sahagun complex has produced major sub-components for vehicles purchased by transit agencies in New York, Kaula Lampur and Vancouver, which purchased Bombardier’s monorail cars for the Skytrain network expansion (those “Innovia” vehicles were also deployed in 2014 in Sao Paulo in time for the FIFA World Cup).

Yet as far as I’ve been able to determine, quality problems have not surfaced with these other customers. Indeed, Bombardier’s Mexican executives in 2013, reported Bloomberg, touted the Sahagun plant as a platform to sell more train systems and engineering services throughout Latin America, but especially Mexico – hardly evidence of chronic quality-control issues.

The problem, I suspect, has far more to do with the order pipeline, and which customer gets the attention and space on the production line.

Consider these examples from elsewhere in Bombardier’s universe. In 2006, Berlin’s transit agency, BVG, placed an initial order for the company’s Flexity trams, and then subsequently increased its purchase, in 2009, 2012 and 2015, bring the total to 189 vehicles. The deal is similar, in quantum and time frame, to the TTC’s.

Except for execution: “As of today, the Berliner Verkehrsbetriebe (BVG) has 115 Flexity model trams in operation,” spokesperson Jannes Schwentuchowski said yesterday. “Until now, delivery of the trams has been punctual. The remaining 74 vehicles are to be delivered until mid-2019.” (BVG celebrated the 100th vehicle delivery last June. While the TTC has waited for two years for 17 vehicles, Bombardier managed to make 15 for BVG in just the past nine months alone.)

In Brussels, meanwhile, the local transit authority last year took delivery of the last of 220 Flexity trams. While the initial order goes back to 2003, the purchase was extended three times, in 2005, 2008 and 2010. The final 87 vehicles, ordered in 2010, were in service just five years later.

(A few more confounding details: while Bombardier’s not had any difficulty delivering on the TTC’s large subway replacement contract, some muckraking by the New York Daily News has revealed that the company is chronically late shipping replacement cars destined for the Second Avenue subway and made in the company’s Plattsburgh, New York, factory.)

So if European customers aren’t having problems with their Flexity orders, why are we having so much difficulty with ours?

It’s worth noting that Bombardier, like many large manufacturing firms, has dozens of plants worldwide. Many are located close to key customers — Bombardier owns factories in both Germany and Belgium — as means of both reducing shipping costs, but also to use local employment as a point of leverage with and over decision-makers.

What about Mexico?

It’s surely not a coincidence that the main customer at Sahagun is Mexico City’s STC, the regional transportation agency, which, according to Bombardier itself, put in an LRV order in 2012 that went into production in 2013.

Bombardier’s Mexican operations, in fact, have very deep roots: during a wave of privatization, the company bought Concarril, a state-owned rolling stock manufacturer, in 1992. STC, according to its wikipedia entry, is a giant transit company with three times the TTC’s ridership.

What’s more, Bombardier has supplied more than 70% of all passenger rail vehicles in Mexico, as well as large segments of the orders from major metropolitan customers in Mexico City, Guadalajara, and Monterrey.

Given all that history, and in particular the heft of a very dominant set of public sector patrons in a country that is hardly a paragon for good governance, it isn’t hard to imagine that an inter-company order of components for a distance customer may play a distant second fiddle when it comes to allocating time on the production line of a 2000-employee factory.

What’s the take away? The TTC has yelled and threatened, and will be suing Bombardier. And who knows what will happen when the next set of major TTC or Metrolinx RFPs go out the door.

But what seems increasingly clear to me is that in a sector where suppliers jostle to be able to claim home ice advantage by pointing to a local plant (and local jobs, and local taxes paid), the logistical or cost benefit to that local customer can be easily squandered when important pieces of those big projects are outsourced to distant factories with their own sets of customers and local priorities. I’m also doubtful that Bombardier Transportation’s new president will have the clout to make significant changes in the way the Sahugan plant prioritizes its customers’ various production schedules. Those sound bites may have somewhat mollified the TTC, but the problem, in the end, seems to be a structural one.

All over the world, in both developed and developing nations, procurement can be a messy and politically fraught affair, so that reality is not unique to Ontario.

In the case of this sordid mess, the TTC and Metrolinx gave Bombardier those huge streetcar/LRV contracts at least in part because the company employed so many blue-collar workers in Thunder Bay, and so it was in Ontario’s interest (as provincial officials believed) to keep the business in the family, so to speak.

They all thought there was a quid pro quo, when, in fact, there was only a quid.

Clarification: According to TTC spokesperson Brad Ross, “Bombardier was awarded the streetcar contract following a competitive, open bid process.”

THE GLOBE AND MAIL

Bombardier to shift production to hasten delivery of TTC streetcars Add to ...Nicolas Van Praet

MONTREAL — The Globe and Mail

Published Thursday, May 19, 2016 6:15PM EDT

Last updated Friday, May 20, 2016 3:52PM EDT

http://www.theglobeandmail.com/report-on-business/bombardier-to-shift-production-to-hasten-delivery-of-ttc-streetcars/article30101340/

Bombardier Inc. is lightening the workload on its passenger rail-car plant in Thunder Bay in an attempt to speed up delivery on a problem-plagued contract for new streetcars in Toronto.

The company confirmed Thursday that it will shift production on one of four contracts the plant is currently executing to another facility in Kingston – specifically, its $770-million contract with Ontario’s regional transit agency Metrolinx – as of October.

The thinking is that will free up the Thunder Bay plant to focus on the $1-billion Toronto Transit Commission streetcar order, which will help accelerate the pace of delivery of the vehicles starting next year, Bombardier says. “We know it’s a tough time for the TTC because of the delays, the late deliveries,” said Marc Laforge, a spokesman for Bombardier. “So we’re taking the measures that need to be taken under the circumstances.… Things will be coming pretty fast starting in 2017.”

The company reaffirmed that it will have delivered about 31 of the low-floor mass-transit vehicles to Toronto by the end of the year, half of what it originally promised. Under a revised schedule shared with the TTC on Wednesday, it is pledging to deliver a further 40 vehicles in 2017, 76 in 2018 and 57 in 2019, for a total of 204.

The move at Thunder Bay is just one of what will likely be several production changes at Bombardier as the company tries to sort out problems with a streetcar deal that has angered public officials and blackened its reputation in Canada’s biggest city.

TTC chair Josh Colle said on April 27 that he wanted to see the train maker take tangible steps to fix the problems before the federal government considers providing any public money to the company as part of the $1-billion investment request currently being evaluated by Ottawa.

Bombardier has already said it will add a second assembly line for the TTC project, and is expected to confirm the location of that line by the end of the month, Mr. Laforge said. The company has also said its assembly site in La Pocatière, Que., will pitch in on the TTC contract with work on the vehicle underframes.

Union officials with Unifor in Thunder Bay have pinned some of the blame for problems with the TTC contract on Bombardier’s Mexico operations, saying components built in a facility there have often been of poor quality. Mr. Laforge declined to provide a detailed explanation on the specific reasons for the delays.

Chris Murray, an analyst at Altacorp Capital Inc., said he’s not concerned that the issues Bombardier has experienced with the TTC contract could signal a broader operational problem at the Berlin-based train unit.

“I think they’ll continue to work through the issues,” Mr. Murray said. “There are contracts from time to time which technically become very challenging. I think that also [plays into] the discussion around bidding what would generally be considered immature designs and develop them in manufacturing.”

The Thunder Bay facility employs about 1,100 workers carrying out four separate contracts: the TTC streetcar deal; a 182-vehicle light-rail car order for Metrolinx; new bi-level cars for GO Transit; and another TTC agreement for new subway cars. That last contract is expected to be completed by the end of this year.

About 60 jobs will be eliminated at the Thunder Bay plant as work gets shifted to other Bombardier facilities, Mr. Laforge said. The company will add to its 300-strong work force in Kingston as the Metrolinx contract gets up to speed, he said. That plant was originally slated to be the testing centre for the Metrolinx cars. It will now build those cars as well.

thestar

TTC considers suing Bombardier after new streetcar delay

By Tess KalinowskiTransportation reporter

Fri., Oct. 16, 2015

https://www.thestar.com/news/gta/transportation/2015/10/16/ttc-considers-suing-as-bombardier-streetcars-delayed-again.html

Furious TTC officials are considering suing Bombardier and want to reopen a debate about whether to bar the company as a supplier in the wake of news that delivery of Toronto's new low-floor streetcars is delayed yet again.

The Montreal-based company is blaming "crimping of electrical connectors" at the same Mexican plant that was responsible for earlier issues involving faulty under-frames and sides.

"The issue was discovered once the parts were delivered to Thunder Bay," said company spokesman Marc-Andre Lefebvre.

The company, which apologized for disappointing TTC riders, said it will add a third shift per day to speed up production.

Toronto, which has 10 new streetcars in service, was supposed to have 20 in full use on the street by the end of the year and 23 in the city, according to a revised schedule issued by Bombardier in July.

Article Continued Below

Now, it expects only 16. Lefebvre said the latest delay can be made up in the new year, when the company will produce one car every five days.

But fed-up TTC CEO Andy Byford, who heard the news from Bombardier president Raymond Bachant on Thursday, said he will believe it when he sees it.

"That's like saying a train's on time when you've re-timed it. I've really tried with them. We have bent over backwards to accommodate Bombardier, but we seem to take one step forward and two steps back," said Byford, who said the cars now in service are spectacular.

To correct the crimping issue, Bombardier has to effectively check 20,000 wires per vehicle.

"It's about 13 to 16 shifts extra per vehicle to do that," he said.

Byford is recommending the TTC immediately begin quantifying the cost of the delivery delays, including the expense of refurbishing old streetcars and running buses on routes that should have had new vehicles.

He wants to immediately move to collect the $50 million in liquidated damages — the maximum the contract allows — that has already been accrued.

"We will not let Bombardier's incompetence hold our patient and loyal customers hostage. We will consider all legal and financial actions at our disposal to address this," said a statement from TTC board chair Josh Colle.

Under the original $1.25 billion order for 204 fully accessible, supersized cars, 73 should have been in Toronto by the end of this year.

thestar

TTC’s new streetcars plagued with manufacturing problems

By Tess KalinowskiTransportation reporter

Tues., May 12, 2015

https://www.thestar.com/news/gta/2015/05/12/ttcs-new-streetcars-plagued-with-manufacturing-problems.html

Laminate that wouldn’t adhere to the parts, and under-frames so badly out of alignment with the walls Bombardier tried to rivet them together: The first vehicles in Toronto’s new $1.2-billion streetcar fleet were so poorly manufactured, the TTC wouldn’t accept them for fear they would break down on bumpy city streets, transit CEO Andy Byford has revealed.

The European design for the streetcar parts simply wasn’t translating to the Mexican manufacturing facility that is supplying parts to the Thunder Bay assembly plant.

“Thunder Bay was finding when they went to attach the under-frame to the sidewalls they weren’t square. You either accept that or try riveting it to create that square alignment. We rejected that. We don’t want it riveted. We want it built properly, because rivets pop,” Byford said.

There should have been about 50 of the new streetcars running on Toronto streets by now, according to the original schedule. But there are only five, with two more expected to come online shortly.

Bombardier spokesperson Marc-André Lefebvre said the company was aware of the manufacturing problems and has been working to fix them.

“I think Mr. Byford’s comments were obviously on items that we have already discussed with the TTC,” he said. “Those are items in the past that we have already acknowledged.

“We took action to make sure that the vehicles we delivered to Toronto were at the highest quality possible.”

Conscious that customers are eager to see the new fully accessible, air-conditioned cars in service, Byford said he is now pushing to have the manufacturing schedule ramped up, first to two cars a month, then by fall to delivery of one every five days.

There should be 30 cars in Toronto by the end of the year, with the Harbourfront, Spadina and Bathurst lines fully furnished. He is adamant that Bombardier meet its 2019 end-date commitment for delivery of the entire 204-car order.

Lefebvre said the company was on track to meet its delivery targets.

It’s been a tricky balancing act between the desire to get the cars and the need to get them right.

“I’m not striving for absolute perfection, because equally customers want the new vehicles,” said Byford, who plans to visit Thunder Bay with TTC chair Josh Colle in June.

There are still issues with loose screws, wiring and electrical connectors; the latter can only be tested once the streetcars are running on the track.

Bombardier is retooling its Mexican operation and the production line in Thunder Bay is getting new quality-assurance processes that catch problems before they get to Toronto. But Byford said he’s made it plain the TTC is not a happy customer.

“Where a defect is not critical and can be rectified later, we do accept the vehicles. There’s been some panels where the aesthetic appearance isn’t perfect. That’s not going to make the vehicle break down. We’ll allow that, on the written assurance that when there’s enough of them that vehicle will go back and get rectified,” he said.

Byford said he was sharing the extent of the quality assurance issues so that TTC riders would understand why they’ve been waiting so long for new vehicles that were ordered in 2010.

“I wouldn’t want them to think we’re passive here. On the contrary, we are hammering Bombardier,” he said, adding that he speaks to his counterpart there regularly and there are daily meetings between the manufacturer and the TTC.

TTC engineers are already helping Bombardier with the commissioning of the new vehicles. To leave Thunder Bay, the vehicles need a partial acceptance certificate (PAC). It is then shipped by train to the TTC’s Hillcrest complex. TTC engineers then issue a final acceptance certificate (FAC). Until that happens, the TTC doesn’t own the vehicle and no money changes hands.

“We will not FAC and therefore pay for, with Torontonians’ tax dollars — we will not accept a sub-optimum vehicle,” said Byford.

The cars now in service “have proved superbly reliable,” he said. One of the two-stage wheelchair ramps has failed once and a Presto device was out of service for about two hours, but otherwise the vehicles have been problem-free.

The TTC has set a target of 35,000 kilometres between failures for the new cars, compared with about 7,000 kilometres on average between failures on the old fleet.

http://bayview-news.com/2015/05/shocking-report-new-ttc-trams-built-out-of-alignment.html/Shocking report: New TTC trams built “out of alignment” May 13, 2015

The Toronto Star says that many of the first streetcars delivered as part of a $1.25 billion order were so poorly manufactured that the TTC refused to accept them. Only five of 50 are now in service. The condition of the cars, as described by TTC spokesperson Brad Ross, is genuinely shocking. The faulty cars had frames that were out alignment with the walls. “Thunder Bay (Bombardier factory) was finding when they went to attach the under-frame to the side walls they weren’t square. You either accept that or try riveting it to create that square alignment. We rejected that. We don’t want it riveted. We want it built properly, because rivets pop,” TTC CEO Andy Byford told the Star. According to the Star, most of the early problems with the streetcars related to the fact that the European-design for the vehicles wasn’t working with the parts being supplied to Bombardier by a Mexican manufacturing facility. Bombardier must still deliver a further 30 streetcars.

http://bayview-news.com/2016/02/cant-deliver-streetcars-now-bombardier-fires-rail-workers.html/Can’t deliver streetcars, now Bombardier fires rail workers February 17, 2016

The hapless Quebec company Bombardier will lay off 7,000 positions over two years in its rail division despite being two years behind in the delivery of streetcars to the City of Toronto. The scandalous incompetency of the Mexican subsidiary has seen a handful of slipshod vehicles delivered, many of them entirely out of alignment and unusable by the TTC. City Council is deciding whether to sue the company. It is an appalling example of the folly — in this case — of buying Canadian. That is how Bombardier got the contract. There seems very little chance that it would have received Toronto’s trolley business if it were not an old Canadian company. On the same day this was announced, the floundering firm said it has a letter of intent from Air Canada to buy 45 of the CSeries 300 jetliner with an option of 30 more. It must be asked if that deal was brokered in the Prime Minister’s office. Bombardier is also waiting to hear about taxpayer money so it can somehow try to survive.