Supply Chain Management Case Study Need it Perfect...

*** Be sure to label each answer with the correct question number so that the CEO (or other reader such as the grader!) can easily find the answer.

*** For essay- or narrative-type questions use MS Word or compatible. There is usually no need to go to a universal format such as PDF. But you can use PDF if you desire with no penalty.

*** Be sure to show your work. For calculations you can use Excel or compatible; or manual and scan the pages into your answer file. Just be sure that the CEO or other reader can find and interpret the answers.

In order to help draw reasonable borders on the case, please prepare your answers primarily on the case contents and the text and other materials. That is not to say that you are limited to only the case and course materials (we are always looking for extra work or slightly different “twists” on the subject matter).

Complete your answers to the CEO’s questions in narrative-type answers (MS Word or compatible).

Light-Up-My-Life, Inc.

At any given time LUML's standard catalog will have about 50 different models of light fixtures. The exact number varies as the company adjusts the product line for current design trends, demand, and the like. As a reminder, LUML has a flexible manufacturing system so adjusting the product line is very easy. LUML has the ability to manufacture custom light fixtures in lots of 100 or more.

Heretofore, LUML has been involved with the US domestic market. However, an architectural design firm is in the process of designing and overseeing the construction management of a pair of buildings in Hong Kong. Some 5,000+ identical light fixtures will be installed in the buildings.

Good news! Because of LUML’s reputation for a quality product, LUML has been contacted and invited to submit a bid on the project.

Even better news! CEO Elise Ennis calls you into her office. Small talk; weather has certainly been warm; how about those Washington Nats -- is this the year that they FINALLY win the World Series?

She says that she appreciated your efforts at filling in with the earlier analyses. She explains the basic scenario on this possible order. Building project in Hong Kong. Possibility of a large order. Would be the first time the company would be involved with an overseas order so no real experience.

She is interested in a summary of the project; a cost estimate; and your recommendation(s), both as a logistician and as a management type, on the overall possibility to pursue the order. Actual questions will be sent over later. She asks you to send her a memo to let her know the details, ok? [Once again, the “ok?” is pretty much a rhetorical question, no?]

You contact Tom Smith (the architectural firm’s POC) and shortly thereafter you receive an email with the particulars that you had requested.

| From: Tom Smith, Clark Architects << [email protected]>> Sent: June 26, 2017 To: [you] @ Light-Up-My-Life.com Subject: Hong Kong building project – light fixtures Good talking to you today. Here is the info that we have available at the present time. #1. Require 5,100 light fixtures all of one style. WE considered three styles (A, B, and C). Style A and style B are still in active contention. As far as we can see, Style C is not going to make the cut. Decision to be made within 60 days. Need delivery in probably 5 6 months. I believe that Jim Smith in LUML manufacturing has the specs. #2. Ship to Hong Kong port where the construction company will take delivery before being offloaded. Regards, Tom |

Well, this is the first time you had heard of Jim Smith’s involvement. So you dutifully trot over to manufacturing operations to talk to Jim.

Jim is aware of the proposal. He explains that, yes, Clark Architects had originally said that there were three designs (style A, B, and C). He rummages through his hold-box and pulls out a piece of paper with notes that he had taken.

| Notes on HK building lights Style A. Basically a cylinder 11 inches high by 11 inches in diameter. The packing box has external dimensions of 12 x 12 x 12 inches. The package boxes cost $.60 each and weigh 1 pound. Estimated cost to manufacture is $4 each. Each fixture weighs 9 pounds. Style B cone shape. Costs $5 to manufacture. For shipping the cones can be nested in packages of six per box. Padding is required so that the fixtures do not rub against each other. The external package dimensions are 12 x 12 x 48 inches. Each package costs $3 which includes the cost of the internal padding. The box itself weighs 4 pounds. The padding weighs 2 pounds. Each light weights 9 pounds. Style C globe shaped. Manufacturing is $6. Shipped 10 per package. Package is 12 x 12 x 90 inches. A filled box weighs 101 pounds. The package costs $3 including the internal padding. HK uses 220-240 v. AC Miscellaneous ** Manufacturing will be done in-house at the Melbourne, FL facility. ** Any of the three given designs requires minimal changes to one of our models & can be easily accommodated with no design cost. Minimum order of any design is 100 so could even do all 3 designs as long as 100 of any style is ordered. ** As long as we know in advance, there is no extra charge for the 220-240 v AC. ** In our catalog, a light bulb is a standard part of the fixture. So no extra charge. ** We add $1 per fixture for other costs just to be on the safe side. ** These estimates should be good for the next 120 days. |

You thank Jim and head over to the shipping section.

Sandy in shipping pretty excited to see someone from “headquarters”. Especially someone who wants to find out some details about shipping and shipping containers. You find out the following information.

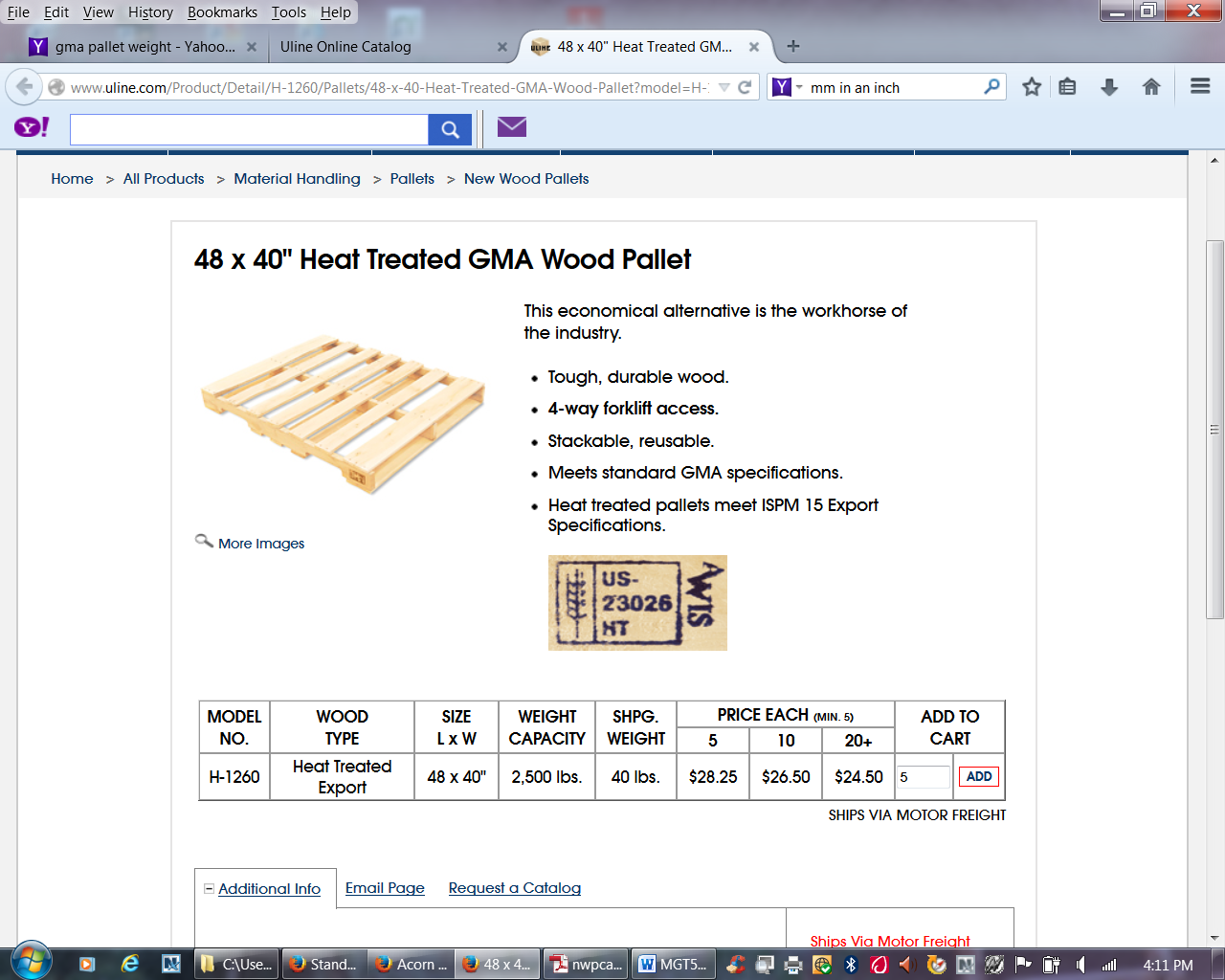

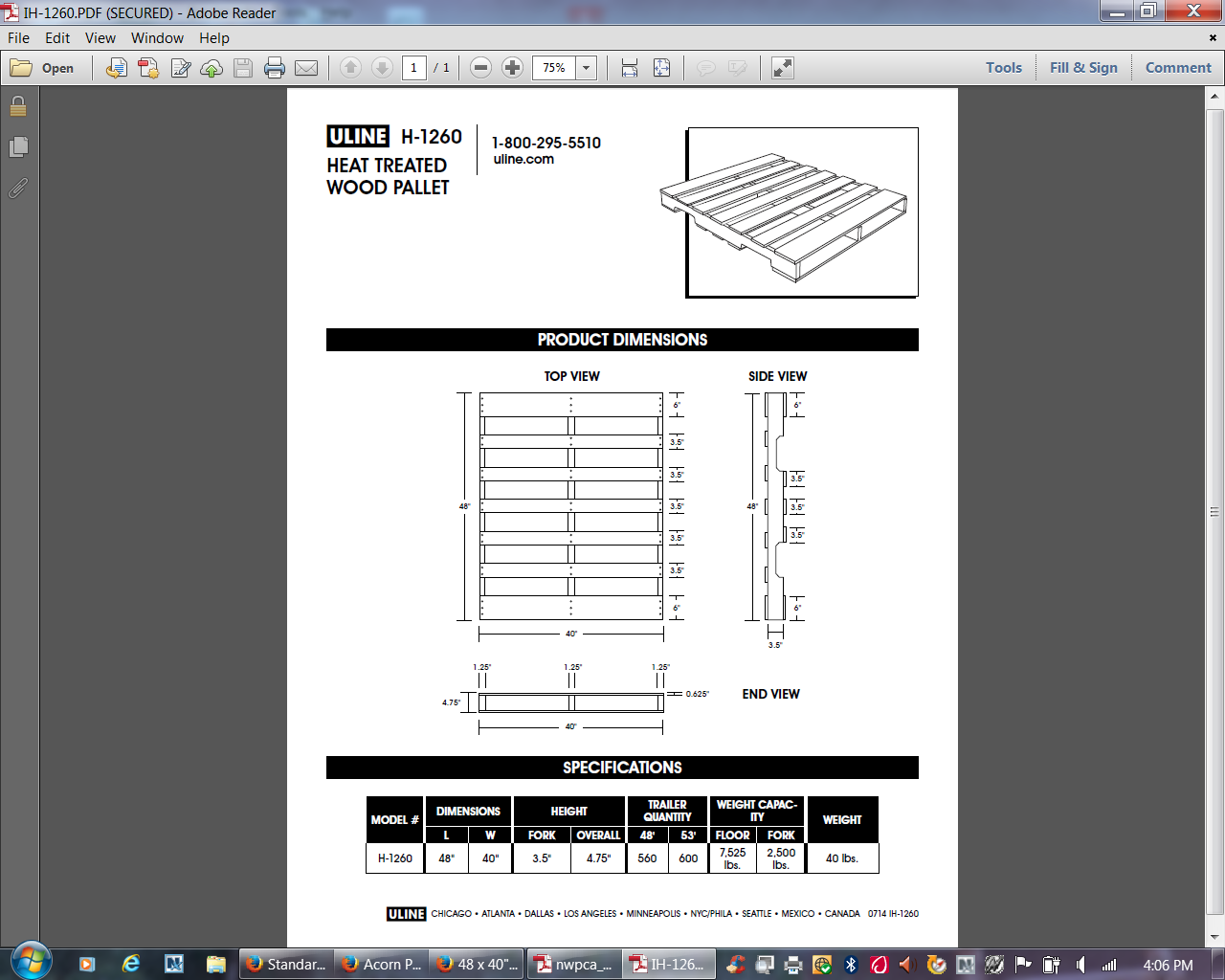

| ** Ocean shipping through the Port of Miami. [To simplify the case we will not consider ground shipping to California & then Pacific Ocean to destination.] ** The land rate per container to Port of Miami is $3 per mile and the trip is 175 miles. ** In a really exciting development, the ISO’s on freight containers were updated not too long ago. Most of the 1995 editions have been replaced by the 2013 version! Actually, the ISO has started selling the standards. So she gives you an excerpt that she had made of the most useful information. [Note in order to simplify the analysis, plan on using only standard 40-foot ocean containers. Use a 40-foot container even if you could actually use a 20-foot container or some other size.] ** Ocean rates from the Port of Miami to the Port of Hong Kong are $65 per ton (use 2,000 pounds). ** No extra charge for the use of the container. ** Shipping company will handle return of the container at no charge to LUML. ** Insurance cost is 2 percent of the value of the shipment ready to be loaded aboard ship in Miami. ** Port charge in Miami is $350/40 ft. container. ** Port charges in Victoria Harbor are $250 per 40 ft. container. ** As indicated in the email, once the ship docks in Victoria Harbor (Hong Kong) the expenses are the responsibility of the buyer. ** Looks like we should use something like the ULINE.COM H-1260 pallet. Sandy burned a copy of the pages – attached. Should buy new pallets since it costs a lot to use used pallets and there is not necessarily a big savings. Need to buy the used pallets & make any needed repairs & get it cleaned/processed for international shipping. [And using new pallets has the added bene of simplifying the analysis just a tad.] ** Packing of the fixtures into the shipping boxes is built into the general LUML warehouse facility operations so there is not an additional cost to the order. ** Stacking on the pallet & shrink wrap on the pallets should be about $25 per pallet. |

| From Sandy |

|

|

| Info from Sandy |

|

|

-=-=-=

FROM SANDY

ocean container dimensions

[Adapted from www-foreign-trade.com reference library]

Ocean Container Dimensions| | STANDARD 20'

| |||

| | |

| STANDARD 40' | HIGH CUBE 40' |

| INSIDE LENGTH | 39'5" | 12.01 m | 39'5" | 12.01 m |

| OPEN TOP 20' | OPEN TOP 40' |

| INSIDE LENGTH | 聽 | 19'4" | 5.89 m | 聽 | 39'5" | 12.01 m |

| 聽 | 聽 | REEFER 20' | REEFER 40' |

| INSIDE LENGTH | 聽 | 17'8" | 5.38 m | 聽 | 37'8" | 11.48 m |

| 聽 | 聽 | FLAT RACK 20' | FLAT RACK 40' |

| INSIDE LENGTH | 聽 | 18'5" | 5.61 m | 聽 | 39'7" | 12.06 m |

| 聽 | 聽 | FLAT RACK | FLAT RACK |

| INSIDE LENGTH | 聽 | 18'6" | 5.63 m | 聽 | 39'7" | 12.06 m |

| 聽 | 聽 | PLATFORM 20' | PLATFORM 40' |

| INSIDE LENGTH | 聽 | 19'11" | 6.07 m | 聽 | 40'0" | 12.19 m |

=-=-=

When you get back to your desk --- as promised – you find a note from the CEO.

[Your name]

Thanks for stopping by today. This order might be a good opportunity for LUML. As I understand it style C is not under consideration any longer. So concentrate on styles A & B. Here are the questions I need the answers to. Send me a memo as soon as you can

Elise

[Q1. Any other information (e.g., assumptions, facts, considerations) that you think we should know when making the decision? [Hint: consider doing this after you do the other answers!]

Q2. How many style A fixtures can be loaded into a standard 40-foot ocean container? How many containers will we need?

Q3. How many style B fixtures can be loaded into a standard 40-foot ocean container? How many containers will we need?

Q4. For style A, what is the total cost to LUML of filling the order up to the port of importation? [Hint: Besides the obvious manufacturing and shipping costs, are there any other costs that we should consider?]

Q5. For style B, what is the total cost to LUML of filling the order up to the port of importation? [Hint: Besides the obvious manufacturing and shipping costs, are there any other costs that we should consider?]

-=-=-=-=

Q6. I was told that there are five basic transportation modes. Comment on the suitability of each to be considered for this order.

Q7. Can this situation be considered intermodal transportation (whatever that means)? Briefly describe how the situation would (or would not) meet the definition of intermodal transportation.

Q8. Describe some of the considerations in selecting the mode and the carrier.

Q9. Briefly describe the “terms of sale” code that might be applied to this case. Explain the rationale for your selection.

Q10. What trade specialists might be used to help us make the decision and/or the shipment? Briefly explain how/why the specialists could help us.

Q11. In the paper today I see that the current exchange rate is USD 1.00 = HKD 7.7991. But I know that exchange rates change all of the time.

*** As the seller, are there any precautions that we should take to help mitigate the risk of a change in the exchange rate?

*** [Assume that LUML has taken action to mitigate the results of a change in exchange rates. So we get a “pure” impact of a change in the exchange rate.] If the exchange rate changes to HKD 7.2000 when the payment is due, what is the likely impact (a) on LUML; and (b) on the purchaser?

In case you are wondering, that is an actual rate on 6/26/2017 from x-rates.com. Using 4 (or even 5 or 6 decimals is pretty standard for exchange rates. For some currencies might even need more than 6 decimals per USD. For our work, use 4 decimals.

Q12. Your recommendations, BOTH as a logistician & overall manager, on whether LUML should pursue this order. [Hint: BOTH certainly suggests that there are TWO answers, yes? The answers may be the same; close; somewhat different; or even opposites! The answer may depend on which “hat” you have on.]

Hint 1: In your memo to the CEO, be sure to answer the questions in an easy-to-find-the-answer format. For example, in my experience we do not normally tell the CEO that the answer is in the spreadsheet at attachment A and leave it at that. For a short or precise answer, then include the answer in the narrative.

Hint 2: As academic work please remember to include in-text references and a reference list. Even in the “real world” it is a very good idea to have your backup ready in case you are asked a question on your work: “where did you get that information?”, “how did you compute that?”, etc.

14