Special project due today by 6PM. Please do not accept if you are not an excellent writer.

Assignment:Please provide a 3 page singles spaced document on the topic below. Please do not provide an overview only address the topic below. Some resources provided also:

Please be specific:

Topic: Identify the changes in Risk Management practices, the Industry and Regulations as a result of the Indiana State Fair Stage Collapse.

Indiana State Fair stage collapse

From Wikipedia, the free encyclopedia

| The stage roof collapsing onto spectators. | |

| Date | August 13, 2011 |

| Time | 8:46 PM |

| Location | Indianapolis, Indiana, U.S. |

| Coordinates |

|

| Cause | Inadequate capacity of lateral load resisting system and a wind gust from a severe thunderstorm. |

| Deaths | |

| Non-fatal injuries | 58 |

The Indiana State Fair stage collapse was an incident during an August 13, 2011, outdoor concert by Sugarland at the Indiana State Fair in which a wind gust from an approaching severe thunderstorm hit the stage's temporary roof structure, causing it to collapse. The structure landed among a crowd of spectators, killing seven people and injuring 58 others.[1]

The members of Sugarland were in a tour bus preparing to come on stage when the collapse occurred at 8:46 p.m. Opening act Sara Bareilles had completed her performance prior to the incident.[2]

Contents[hide]

1Events leading up to the collapse

1.1Discussions about delaying the show

1.2Evacuation announcement and concert cancellation

1.3Collapse

2Investigation

2.1Cause of the collapse

2.2Design, construction, and inspection

2.3Preparedness, communication, and response

3Legal cases

4References

Throughout the day and evening of the concert, the National Weather Service issued notices and warnings predicting strong thunderstorms. Messages about the forecasts were relayed to various State Fair personnel via an automated text-messaging system.[2]

At 8:00 p.m., Cindy Hoye, Executive Director for the Indiana State Fair Commission, held a meeting to discuss what effect the weather forecast would have on the 8:45 p.m. start time for the Sugarland show. Members of the meeting were told that the storm was forecast to arrive at 9:15 p.m., 30 minutes after the concert was to begin. Hoye wanted to delay the show until the weather had passed.[1][2]

An official took this message to Sugarland's managers, who said they preferred to go on with the show as scheduled and only stop if weather conditions worsened. The managers only knew about the rain, not the lightning, wind, and hail that were expected.[2] They decided to start the show just 5 minutes late (8:50 p.m.) to allow the band time to warm up.[2]

When the band's decision got back to Director Hoye, she accepted, assuming the band had the final say.[2] Since the storm was to arrive at around 9:15 p.m., there would still be time for them to perform some of the show.[2]

Evacuation announcement and concert cancellation[edit]At around 8:30 p.m., Director Hoye encountered State Police Captain Brad Weaver. Weaver was concerned that the approaching weather would pose a threat to public safety, and recommended that Hoye cancel the show. He also recommended they put together an evacuation plan for the crowd. Hoye directed her staff to make preparations for an evacuation.[2]

At 8:39 p.m., the National Weather Service issued a severe thunderstorm warning indicating that hail with a diameter of 1 inch (25 mm) and winds over 60 miles per hour (97 km/h) were expected. This warning was not communicated to Executive Director Hoye or Captain Weaver, who were still anticipating the storm arriving at 9:15 p.m.[2]

At 8:40 p.m., Director Hoye dictated a message to an announcer, who delivered it to the audience at 8:45 p.m.[2] The announcer stated that a storm was approaching but that the show would go on. He gave instructions on how to evacuate to the buildings nearby in case conditions got worse, but there was no directive to actually proceed with an evacuation.[3]

Collapse[edit]After hearing an announcement that the show was going to continue, Captain Weaver confronted Director Hoye and reiterated that the show should be called off. The two agreed, and began walking to the stage to make a second announcement. However, at 8:46 p.m., a wind gust (possibly a gustnado) hit the stage structure. Just when it hit, the stage collapsed—before they were able to announce the evacuation.[2]

Tammy Vandam, 42; Glenn Goodrich, 49; Alina BigJohny, 23; and Christina Santiago, 29, all died at the scene. Stagehand Nathan Byrd, age 51; Jennifer Haskell, 22; and Meagan Toothman, 24, later died in the hospital from their injuries.[4]

Investigation[edit]The Indiana State Fair Commission hired the engineering firm Thornton Tomasetti to lead the technical investigation into why the stage collapsed. The same firm investigated the collapse of the World Trade Center on 9/11 and also investigated the Interstate 35W bridge collapse in Minneapolis.[5]

In addition, the public safety and crisis management firm Witt Associates was hired to investigate the State Fair's preparedness and response to the incident. James Lee Witt, the company's CEO, was the director of the Federal Emergency Management Agency (FEMA) for the Clinton Administration.[6]

Cause of the collapse[edit]

One of the Jersey barriers used as ballast for the stage roof guy lines after it was pulled down a flight of stairs by the collapsing stage (background). The lack of resistance provided by these barriers was found to be the primary cause of the collapse.

According to the final incident report released by Thornton Tomasetti:

The failure ... was due to the inadequate capacity of the lateral load resisting system, which was comprised of guy lines connected to concrete "Jersey barrier" ballast.[7]

The concrete barriers used as anchors for the guy lines were not fixed in place; they resisted loading only by friction with the ground and through their own weight—about 4,200 pounds (1,900 kg).[7] Just before the collapse, wind loading caused several of the barriers to slide or pivot from their original positions, allowing the top of the truss structure to lean toward the crowd. The subsequent bending forces within the support columns were too large, and the structure collapsed under its own weight.[7]Measurements indicated that the total weight was 70,000 pounds (32,000 kg).[8]

Multiple components within the lateral load resisting system were found to be insufficient:[7]

Ballast system: The Jersey barriers, as arranged at the time of collapse, could only resist winds ranging from 25 to 43 miles per hour (40 to 69 km/h), depending on wind direction; however, the actual wind speed was about 59 mph (95 km/h). The building code required the structure to withstand winds of 68 mph (109 km/h).

Guy lines: Even if the ballast had been sufficient, the structure still would have failed, because the synthetic webbing ratchet straps and wire rope used as guy lines would have been loaded beyond their capacity.

Structure connections: The fin plate connections attaching the guy lines to the top of the truss structure also had insufficient strength and would have failed.

The separation and billowing of the roof tarp was found not to be a cause of the collapse, because the collapse sequence had already begun before the membrane added additional forces.[7]

Design, construction, and inspection[edit]The report also points out a number of procedural factors that either contributed to the structural problems or prevented them from being discovered:[7]

The catalog provided by the structure manufacturer, James Thomas Engineering, did not contain enough information to properly design the structure.

When the same structure was reviewed by a engineer from James Thomas Engineering in 2010, the analysis was inadequate.

There was no engineering review of the Sugarland rigging plot before it was affixed to the structure.

The installation of the structure deviated from the directions provided in the analysis by the engineer from James Thomas Engineering (in addition to the analysis being inadequate).

There was no engineering review of the structure after it was erected by Mid America Sound Corporation.

The State of Indiana governing code waived important requirements for temporary structures such as the one that collapsed.

The Indiana State Fair Commission staff did not have the appropriate information or knowledge about the structure to evaluate its use during the fair.

Several issues were found with the level of preparedness and the actions of State Fair officials and Sugarland representatives on the evening of the incident that contributed to the number of casualties:[2]

The Indiana State Fair Commission had taken some steps to prepare for an emergency, but the overall state of preparedness was not adequate for an event the size of the Indiana State Fair.

The Indiana State Fair Commission also lacked formal protocols for delaying, postponing, or cancelling a production. As a result, it was not clear who had the authority to make decisions regarding the concert.

Weather forecasts were not properly communicated.

The response to the incident, however, was successful, with all severely injured patients being transported to hospitals within 80 minutes.

Several lawsuits were filed after the tragedy. In 2014, the largest lawsuit (representing multiple plaintiffs and multiple defendants) was settled for $50 million in damages. In the aforementioned lawsuit, the State of Indiana settled for paying $11 million, and the other defendants (including Live Nation and Sugarland) settled for paying the balance of the $50 million award ($39 million).[9] However, defendant ESG Security, Inc. (who lost one of its own in the collapse)[10] denied liability and did not settle. On September 14, 2015, ESG won on summary judgement and was dismissed from the case.[11] ESG was the only defendant dismissed from the case via the summary judgment process.[12]

https://en.wikipedia.org/wiki/Indiana_State_Fair_stage_collapse

Temporary Structure Failure - Case Studies

Collapses from 2008 to Present

Thomas J. Kleinosky, Bachelors and Masters of Architectural Engineering Penn State 2012

Temporary structures are a structure without a permanent foundation and after a certain period of time the structure is removed. Figure 1 is an example of a temporary structure, this structure is the Grandstand Stage at the Indiana State Fair that collapsed in 2011, Figure two is a picture after the collapse. Some other examples of these structures are concert stages and roofs, audience bleachers, and shoring used during construction, but this case study will focus on concert stages. These temporary structures are very convenient due to the low cost of materials, and quick assembly time. The issue with designing temporary structures are the variety of these structures ranging from large structures for the Rolling Stones, Bon Jovi, or Madonna concerts to smaller structures such as outdoor weddings. The variety of these structures makes it difficult to develop a standard for all temporary structures, and in addition the current codes vaguely discuss loading on temporary structures. This leaves the engineer to use his own judgement based on local and municipal codes to determine appropriate wind loads for the structure. However even though these structures may vary in size and use they all have three main structural components involved in resisting the gravity and or lateral loads, these three systems are (LABC 2012):

Foundation - This is designed to support the gravity load of the structure as well as to hold the structure down when lateral loads are applied and an overturning moment is present

Superstructure - This part of the structure is the scaffolding type structure that supports the gravity loads of the structure, for example the audio and lighting equipment and the people whether they're erecting the structure, performing, or working the lighting equipment.

Stability System - This consists of bracing and other member to resist the lateral loads, these members can consist of diagonal bracing, the use of cables and jersey barriers, or other structural elements

| |

| Figure 1: Indiana State Fair Grandstand Stage - Image Courtesy of Thornton Tomasetti |

| |

| Figure 2: Collapsed Grandstand Stage at the Indiana State Fair - Image Courtesy of Indiana State Police |

When designing a building the design engineer follows building code as well as municipal code while designing the structure, and the building at a minimum must meet the requirements of these codes. However for temporary structures there is not a regulated or concrete method for determining loads on temporary structures such as stages, temporary roofs, bleachers, and other facilities that are only erected for a short period of time. Leaders of the industry should take the initiative to create an industrywide standard that not only govern the safety of these structures, but also balance costs with safety benefits (Gorlin ASCE 2009).

Faulty design of temporary structures is not necessarily the fault of the design engineer, the lack of a worldwide standard for designing temporary structures doesn't help. The industry standards today do not give the design engineer enough information to determine loads and other considerations concerning the design without the engineer having to use their best engineering "judgement". As Gorlin describes in his article in Structure Magazine, due to lack of guidance engineers must used building codes in conjunction with their own judgement in order to determine applicable wind loads. He describes an event stating that if a man were to climb a ladder "a temporary structure" he will not wait until the wind reaches "56 percent of the allowable code wind" before dismounting the ladder. What he is trying to get across is that the engineers must factor in the human element when designing temporary structures, when will the people at the event recognize the integrity of the structure is being jeopardized and when to dismantle it. This is something the practicing engineer cannot control other than stating the maximum allowable wind load, and which requires constant wind speed monitoring and communication with the event staff. Also as with most storms wind speeds increases over time therefore the engineer also needs to consider the duration it takes to dismantle the structure as well as the man power needed to dismantle it (Gorlin Structure 2009).

The IBC, International Building Code, briefly defines a temporary structure, it states that a structure which is erected for 180 days or less can be determined to be a temporary structure (Gorlin ASCE 2009). However following this state ment there is no further reference to a guideline or a procedure to determine applicable loads and or to assist in the process to design the structure. The ASCE 37 standard, Design Loads on Structures During Construction, then may be utilized to determine applicable wind loads which lowers them due to the structure having short term exposure, but again no further information regarding the design of the structure (Gorlin Structure 2009).

This lack of standard has happened in the past and similar to temporary structures, federal buildings had no governing standard for progressive collapse to resist a building from collapsing after a terrorist attack. Before terrorist attacks were a recognizable threat there was no such procedure to design a building for progressive collapse however after recent attacks it was determined that a progressive collapse analysis must be incorporated into the design for federal buildings but there was no clear procedure. Following that the General Services Administration (GSA), Department of Defense (DoD) both produced documents providing the design engineer with step by step procedures as well as a mathematical examples. This is the next step that needs to be taken in the industry of temporary structures, there needs to be a widely accepted set of standards to be developed from a renown industry group such as ASCE or the Entertainment Services and Technology Association (ESTA,

http://www.plasa.org/welcome/). Some standards do exist for temporary structures such as PLASA (Professional Lighting and Sound Association) for instance, they published standards on how to safely erect a temporary structure as well as what to do in an emergency situation. However these standards do not have much of a voice due to it falling under ANSI (American National Services Institute), because of it being an ANSI standard PLASA's standard is more of a recommendation (Hasler 2011).

Any new guidelines/standards should consider wind loads for design, maximum time for dismantling the structure, monitoring and operational procedures, and also a wind gauge should be present and monitored to determine when the structure should be dismantled (Gorling Structure 2009). Most importantly the standard needs to consider constant weather monitoring and an emergency evacuation/dismantling plan. During the event, an experienced staff needs to be at hand in order to dismantle the structure swiftly and safely, once the structure is determined to be unsafe. Together the event should have at hand a professional to read the wind gauge, construction crew to dismantle the structure, an engineer as a consultant, and an event supervisor in case the weather is declared too dangerous for the event to proceed.

In the following case studies, the Indiana State Fair and the Ottawa Bluesfest, it can be seen how lives could have been saved by having proper weather monitoring and an evacuation plan as well as how the lack of design and construction incompetence affects the structural integrity of these structures.

On August 13, 2011 roughly 12,000 people were awaiting a Sugarland Concert at the Grandstand Stage (see Figure 1 and 2) at the Indiana State Fairgrounds when a windstorm rolled through and collapsed the Grandstand Stage taking the lives of seven people and injuring nearly forty others. The audience was briefly warned to vacate the area in an event of a storm, however the warning was given only moments before the stage collapse and the audience had no time to evacuate (Witt 2012). The structure was 107 feet by 57 feet with a peak elevation of 56 feet above the ground/track elevation (Thornton Tomasetti 2012).

As a result of the collapse, Thornton Tomasetti investigated and created an analysis of the collapse to determine cause of the collapse whether it was insufficient design, poor construction, or misuse, along with Thornton Tomasetti, Witt Associates also provided a detailed independent report on the collapse.

Thornton Tomasetti began the analysis by trying to first determine what the wind forces were at the time of the event and compare them with the building code standards. Using the determined wind loads, Thornton Tomasetti created a finite element model of the structure to determine it's response to the winds at the time of the event. Finally, how would a "reasonable" engineer design a temporary stage structure with provisions for the required resistance to forces that meet code stipulated factors of safety (Thornton Tomasetti 2012)

During the day of the event Ray Allison, the director of the Indiana State Fair's (ISF) Public Safety and Logistics, had been given reports for the National Weather Service, which he had relayed the information to other ISF personelle. Around 7:00 P.M. he relayed that high winds and heavy rain was expected between 9:00 and 9:30 P.M. At 8:00 P.M. a meeting was held to discuss the weather at 8:45 P.M. during the time of the event, the meeting did not focus on public safety. Following the meeting a discussion with Sugarlands band management was had to discuss the idea of delaying the show, however the threat of rain was the only concern and the band manager decided to proceed with the show(Witt 2012).

The police had no involvement in these prior discussions or meetings which were focusing on the rain, not the oncoming wind. Sometime after the 8:00 P.M. meeting Captain Weaver, of Indiana State Police, approached Director Hoye, the ISF's Executive Director, about his concerns on the storm and the publics safety. Captain Weaver and Director Hoye then discussed an evacuation plan, and Director Hoye instructed her staff to begin preparation of evacuation in the Grand Stand area. At 8:39 the National Weather Service declared a severe weather warning for the area, neither DIrector Hoye or Captain Weaver received the warning(Witt 2012).

As the event neared Director Hoye gave a message to Robert Richards, a local radio personality, to announce to the audience that the show was going to start briefly. Captain Weaver however did not expect Director Hoye to send this message, he confronted Hoye and they went together to tell the audience to immediately evacuate the area but before they were able to give the message the structure collapsed(Witt 2012).

At the time of the collapse the registered wind speed was approximately 59 MPH. According to the ASCE7, Minimum Design Loads of Buildings and Other Structures, the state of Indiana requires a wind speed of 90 MPH however per ASCE37-06 that value can be reduced by 75% and furthermore according to ANSI (American National Standards Institute) there is an allowance for the wind speed to be reduced to 40 MPH if the structure can be disassembled quickly. Thornton Tomasetti used the wind speed of 68 MPH in their analysis, 75% of 90 MPH, as the applicable wind load for the ISF stage(Thornton Tomasetti 2012).

Based on the conclusions of Thornton Tomasetti's (TT) report there were four structural failures that contributed to the cause of the collapse of the Main Stage, these failures were:

Jersey Barrier Capacity

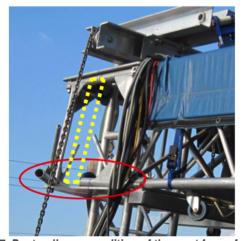

Figure 3: Eastside Jersey Barriers, Guy Lines, and Fin Plate Layout - Photo Courtesy of Thornton Tomasetti

Guy Line and Ratchet Strap Capacity

Fin Plate Capacity

Roof Membrane

In Figure 3 courtesy of Thornton Tomasetti, the layout of the jersey barriers can be seen as well as their corresponding guy lines and fin plates. The layout of the Jersey barriers were deemed insufficient for the applied wind loads, after the analysis it was determined the layout of the barriers were only capable of resisting wind loads from 25 to 43 miles per hour (Thornton Tomasetti 2012). Also when one Jersey barrier failed, and failure in this case is either sliding, tipping, or rotating, the rest of the barriers went soon after and collapse was immediate.

Under the conditions of the 59 MPH wind load, the guy lines ultimate strength was compared to the forces determined from Thornton Tomasseti's analysis and the guy lines were over stressed, by up to 10 kips in certain areas. Even if the guy lines were designed to resist the force, the structure would have still collapsed due to the insufficient strength of the fin plates(Thornton Tomasetti 2012).

| |

| Figure 4: Failed Fin Plate - Photo Courtesy of Thornton Tomasetti |

The fin plates, located at the top of the structure connecting the guy lines to the structural trusses were under designed for the applied wind load of 59 mph. It was determined the failure of the fin plate was not the fin plate however it was it's connecting elements and the bending capacity of the bottom tube was what governed the design of the fin plate. In Figure 4, courtesy of Thornton Tomasetti, is an image of a failed fin plate, the area outlined in yellow is where the fin plate used to be and the area circled in red is the failed bottom tube causing the failure of the fin plate (Thornton Tomasetti 2012).

The final contributing cause of collapse was the release of the roof membrane. At the time of collapse the tarp had torn away from the ridge panel due to the weak connections (ropes and ratchet straps), when this occurred the tarp on the leeward created a drag force. However the drag force did add additional lateral loads on the structure. It was determined that the structure was already in the process of collapsing prior to the tarp tearing and the tarp just expedited the process (Thornton Tomasetti 2012).

In the conclusion of the report produced by Thornton Tomasetti they include recommendations for those involved with the design, construction, or management of temporary structures. The recommendations are broken down into four categories:

Permit and Enforcement Process

Codes and Standards Requirements

Lateral Systems

Operations

The Permit and Enforcement Process, is further broken down into having a competent design engineer, submission of permit applications and design review, and an inspection of the completed structure. The competent engineer is defined as one who is experienced in the design and evaluation of temporary structures with complex loading configurations. Next, the structure should obtain a permit prior to having a thorough review of the design and the calculations and assumptions involved in the design. Finally, after the structure has been erected, a qualified inspector should be involved to inspect the structure and determine whether or not the structure has been erected properly.

There are multiple subtopics involved in the Codes and Standards Requirements, they are:

Design Parameters Based on Use

Design Parameter Based on Variability

Design Parameters Based on Site Conditions

Factors of Safety Based on Variability

Speciality Reference Standards

Modifications of Model Reference Codes and Building Standards

The first four categories relate to creating a better standard and bigger emphasis on the design of temporary structures. Temporary structures even though they are only temporary are just as important as permanent structures when it comes down to the safety of the public. With the variance in these types of structures a standard approach should be created and factor of safety should be incorporated due to this variance. WIthin the standard there should be more specific site location factors based on elevations, environmental conditions, ground conditions, soil conditions, etc. the one size fits all thought process cannot be used here due to the variance of locations and elevations of these structures.

The next category Thornton Tomasetti discusses is the lateral system of the structure. The four areas they discuss are the ballast system, mechanical anchoring points, shared anchoring points, and geometry of the guy line systems. TT discusses that the use of a movable ballast system which relies on self-weight and friction is not a desirable method to resist lateral loads in a stage structure. These ballast systems are the Jersey barriers, and from TT analysis a considerable amount of Jersey barriers would have been necessary to resist the applied wind loads. In place of a movable ballast system, when applicable, mechanical anchor points should be utilized to resist the lateral loads. Not only are these a better system due to the anchor point is fastened and cannot move but during cyclic loading such as an earthquake these are a much more optimal choice.

Finally the last category is operations. A sufficiently designed structure cannot resist all loads no matter how well the design has been done, therefore one must determine a what loading all operations must stop. These operations cannot be carried out by the design engineer, they must be followed by the staffing at the event and a constant weather monitoring must also be utilized. Also the time it takes to dismantle a structure must be considered, and it must be known at which wind speeds should an evacuation take place and to not even bother dismantling the structure.

The following is a video of the collapse of the Grandstand Stage.

On July 17, 2011 a predicted thunderstorm rolled through the 2011 Ottawa Bluesfest and a gust of wind collapsed the stage that the band Cheap Trick was playing on. Fortunately there were no fatalities, the collapse resulted in only four injuries and only one of which was serious (Praetorius 2011). The stage was 45 meters wide and 17 meters wide, there were wind flaps on the rear and side walls which were removable (Cobb 2012). The stage was constructed by Mega-Stage a division of Groupe Berger, Berger was involved in the construction, supplies, daily operation and removal of the main stage, the one that collapsed (Gordon 2012).

Two investigation reports were performed by Health and Safety Inspector Jason Gordon and another report, which has yet to be released, was done by Robert Molina, engineer (Cobb 2012). In Gordon's report he discusses the collapse and the events leading up to it, and the weather/environment impacts during the event of the collapse. From his report it is clear that the collapse is a result of poor construction as well as poor ownership supervision and lack of communication.

One of the main issues with the stage collapsing were the side and rear wind flaps that could not be removed at the time of the event. Earlier that week on the same stage the Black Keys had played and the stage experienced a strong windstorm and the zip-ties that were holding the rear and side walls together were taken down. Following the show and once the storm had passed the walls were replaced, however instead of using zip-ties, the on stage crew used cable ties. The reason for using zip ties instead of cable ties are that zip ties are made of a plastic material and can be cut, however the cable ties made out of wound wires are much more difficult to cut. Prior to the stage collapse, there were witnesses who claimed that the stage hands were unable to release the ties because they were unable to cut/sever them. At the time of the collapse the wind was recorded at 117 km/h and the structure with the wind walls attached was only able to withstand 80 km/h however if the walls were removed it could resist up to 120 km/h. As a result of the collapse, engineer Molina states "Groupe Berger failed as an employer to take reasonable precaution of releasing the wind walls despite being aware of the forecast for damaging winds, therefore failing to take every precaution reasonable in the circumstances for protection of the worker" (Cobb 2012).

In addition to the winds walls being unable to be removed Molina also found that column connections had less than the required amount of bolts, as well as the bolts used were smaller than required. These findings were determined not to be the direct cause of the failure of the structure but the poor workmanship by Berger did not attribute to resisting the collapse (Cobb 2012).

Concluding Gordon's investigation he determines the causes of the failure to be due to lack of an operation plan and proper maintenance. Berger was not able to provide an Operations Management Plan specific to the stage and set-up used at the Ottawa Bluesfest Concert. The wind walls that were designed for the stage were to be removed in the case of strong winds to increase the integrity of the structure however Berger failed to release the walls which compromised it's strength. The wind walls were not able to be removed due to the lack of a plan to reattach the walls prior to them being removed the week before on the same stage due to high winds(Gordon 2012).

Fortunately there were no fatalities in this collapse however it does bring up some lessons that need to be learned by the construction industry involving temporary structures. First off a plan must be devised while maintaining the structure and having a supervisor on site during the event monitoring the weather and that clearly understands what to do in case of high winds. Also that person needs to understand how to properly reattach the wind walls that are connected to the structure, the problem with this collapse is the walls were improperly put back on and when the high winds came they could not be removed. Next, the structure needs to be inspected prior to every event or even every day by qualified individuals, if this was performed it would have been known the wrong ties were used and they could have been replaced before the next event.

In this case the cause of the failure was not due to poor design of the structure, it was due to the lack of a plan and in general the contractor failing as an employer. Even though this is a temporary structure and some may regard it as not as a critical structure, it must be erected and maintained very carefully in order to prevent more collapses in the future.

What is being done?In response to all of the recent collapses that have occurred in the United States, Canada, and the UK in recent years professionals are becoming more aware of the degree of seriousness involved in erecting and designing temporary structures as well as the need for a standard. Most recently the Standing Committee on Structural Safety (SCOSS, see http://www.structural-safety.org/) published an alert that is directed towards those who commission or procure licenses for temporary stages or any other temporary structure. These people include:

Owners of the sites

Contractors

Designers

Insurers

Local authority officers

Building control officers

To ensure structural stability and the safety of the audience/occupants SCOSS has devised a plan for the local authorities to ensure their Safety Advisory Group follows. Prior to building the structure the plan suggests that the following should be presented and review:

Design Documentation

Evidence of Competence of the Designer

Evidence of an Independent Design Check

Having design documentation at hand prior to the construction of the structure enables the owner/builder to clearly understand the project and have the opportunity to overlook the calculations and members involved in the project(SCOSS 2012). By reviewing the design and calculations prior to building the structure, discrepancies in the drawings or unclear calculations or details can be discussed and cleared up. Next, providing references and background checks of the engineer at hand can give a clear indication of whether or not the engineer can be trusted, someone with a background of incompetence should be disregarded as the design engineer. Finally, the design drawings should be reviewed by an independent engineer to give the drawings another set of "eyes" to pick up certain things the design engineer may have overlooked(SCOSS 2012).

Prior to the event:

Independent Erection Check

Completion Certificate

Similar to the design check the erection check should be performed by a competent engineer to ensure the structure has been erected as required in the construction documents. Once the erection is complete and it has been reviewed by the independent consultant, a certification of completion must be made by the event organizer declaring the structure has been reviewed and it has been erected properly(SCOSS 2012).

During the event:

Wind speed monitoring

As discussed prior in this article, the wind speed must be constantly monitored throughout the event and incase the wind speeds start to creep to the maximum allowable wind speed an authority must be notified immediately(SCOSS 2012). If this plan were to have been implemented on the ISF's and the Ottawa Bluesfest stage the collapses could have been prevented.

https://failures.wikispaces.com/Temporary+Structure+Failure+-+Case+Studies

http://www.in.gov/dhs/2376.htm

Requirement for Temporary Stages

Chapter 16 of the Indiana State Fire Building Code- Structural Design

http://www.in.gov/dhs/files/20120410121621937.pdf

INDIANAPOLIS, Indiana —

Monday marks exactly one year since the Indiana State Fair stage collapsed, killing seven people and injuring 58 others.

High winds sent stage rigging crashing onto a crowd of fans awaiting a concert by country duo Sugarland, causing the fatalities.

Advertisement

RELATED CONTENTAppeals court rules against Cincinnati girl hurt in stage collapse

Cincinnati girl hurt at state fair challenges Indiana damages cap

Deal may be near in Indiana stage collapse suit

One of the seven killed, Megan Toothman, 24, lived in Cincinnati. She was at the concert with her cheer squad from Turpin High School. Toothman, the varsity coach of the team, was taken off life support a week after the collapse.

Several other local people managed to survive the tragedy, including Jaymie Polet, one of Toothman's cheerleaders.

Polet, her mom and her 10-year-old sister were all hospitalized after the collapse. Polet suffered from a skull fracture and broken bones, but survived the incident.

Shannon and Jade Walcott, a mother and daughter pair from Florence, Ky., were also among those who survived the collapse.

The fair will come to a stop from 8:46 p.m. to 8:50 p.m. today to mark the tragedy.

"It's going to be a tough day," said Laura Magdziarz of Morocco, Ind., who was injured when the grandstand toppled. Her then-3-year-old daughter, Maggie, was also hurt.

Magdziarz said Monday she planned to buy seven pink roses adorned with ribbons featuring the names of the seven who died.

Rides and shuttle buses will stop at 8:30 p.m., and concessions will turn off all music. Fair officials said they anticipated a crowd would gather at a memorial to the victims outside the grandstand.

The collapse spurred key changes at the fair after two months-long investigations found that the stage rigging wasn't strong enough to meet state building codes and that the fair lacked a fully developed emergency plan.

The Indiana State Fair Commission in May hired venue manager David Shaw as chief operating officer to handle day-to-day operations and Jessie Olvera as director of safety and security. A month later, it unanimously approved a 425-page emergency management plan that adopted recommendations made by consultant Witt Associates and formalizing procedures that already were in place but not used the night that the grandstand collapsed. The new plan gave Shaw the responsibility for postponing or canceling events amid threatening conditions or, in his absence, Olvera.

State lawmakers also approved a measure requiring inspections of temporary stages at the site until 2014. They plan to meet next month to study permanent regulations.

Indiana has already paid $5 million to victims of the collapse and has added $6 million to a proposed $7.2 million settlement from stage owner Mid-America Sound Corp. and James Thomas Engineering. That payment, which requires victims to agree not to sue, is pending approval from the two companies.

Lawsuits over the collapse are pending in Indianapolis. A judge has ordered all sides to enter mediation in hopes of reaching a settlement by the end of 2013.

Monday's observance comes a day after five people, including the fair queen, suffered minor injuries when a stagecoach overturned during a performance ahead of a hitch competition in the Pepsi Coliseum. Fair officials evacuated the arena and delayed the competition.

http://www.wlwt.com/article/ind-state-fair-remembers-stage-collapse-one-year-later/3524403

A 425 page Comprehensive Emergency Management Plan was created. I found the highlights in powerpoint :-)

https://ppt-online.org/194087