Write a professional project report presenting all details and results for their design. The report must include: 1. Cover page (project title and complete names of all team members). 2. A “Frame of R

Introduction

As societies continue to grow the demands that are placed onto consumer companies are also growing at a rapid rate. One of the major problems in which is faced within the transportation and logistics industry is the problem of not being able to meet consumer needs on a daily basis without the overbearing workload on human labor. Many companies are currently seeking an ideal solution to this problem in order to maintain stability within the daily operations of packaging and handling products for shipment in a timely manner.

In this report, there lies a solution to this packaging and handling problem that is found within the warehousing and freight industry. A group of engineers has created a Robot Package Handler in which is designed to handle packages by moving them from shelves or other areas and placing them onto pallets for shipment. This robot was designed to work consistently throughout the day with a fully charged battery pack with little or no requirement of taking long breaks, which in turn will easily carry out the work of three men and promote an efficient work environment.

The Robot Package Handler was created keeping in mind all the expenses in which companies will have to withstand. This being the case, the robot is designed in such a way choosing very strong and reliable inexpensive parts assembled with simplicity. The main components of this machine include a number of servo motors, a battery pack to carry out each daily task, a sturdy frame along with four legs and a grabber arm to grip firmly onto packages. Each component was designed to be easily serviceable which in turn will lead to a fair cost in maintenance for each unit. There are many other types of warehouse robotics which are currently in use at the moment such as the Automated Guided Vehicles (AGV’s) and the automated storage and retrieval systems (AS/RS) but research as shown that it requires a hefty price to obtain such machineries and maintenance is far from inexpensive due to the complex parts and assemblies. Unlike these robots, the duties of the handler is unique by performing duties in which is required by an order picker in a typical warehouse.

More in depth details on how this robot operates with its fully automated software interface and the material that was chosen along with the cost, strength and weaknesses of the machine will be further discussed in this report. The assembly of the unit is also instructed clearly for both the robot grabber arm and its body.

How the Product Works

Robot Package Handler Design

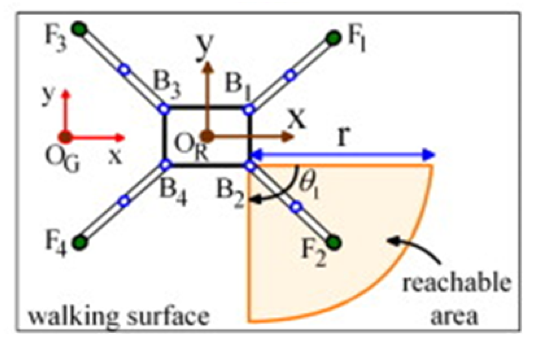

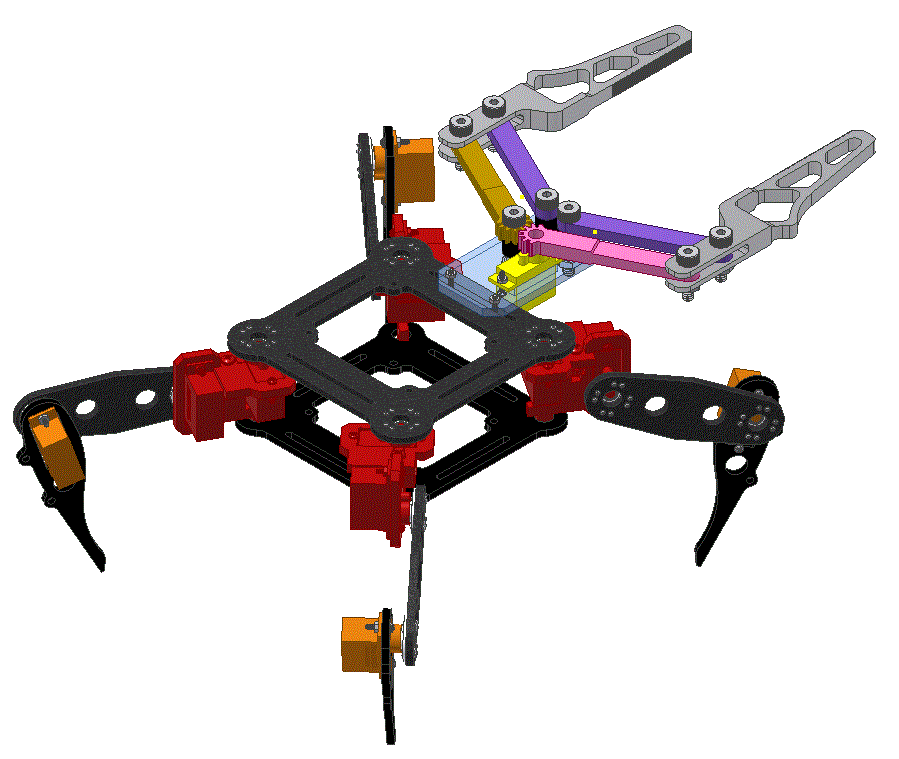

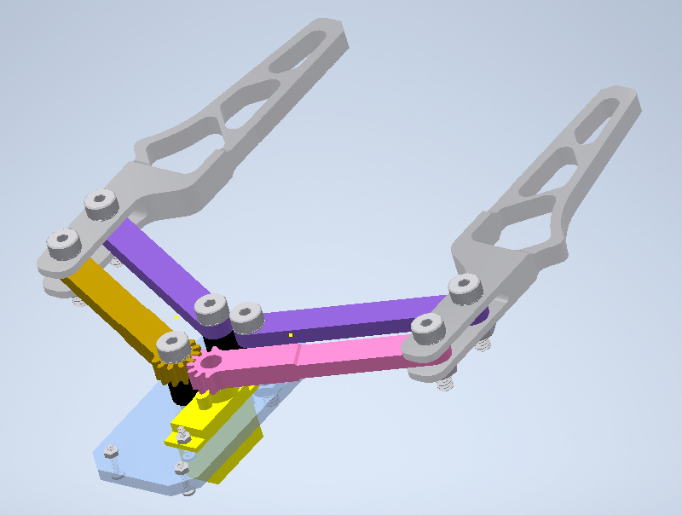

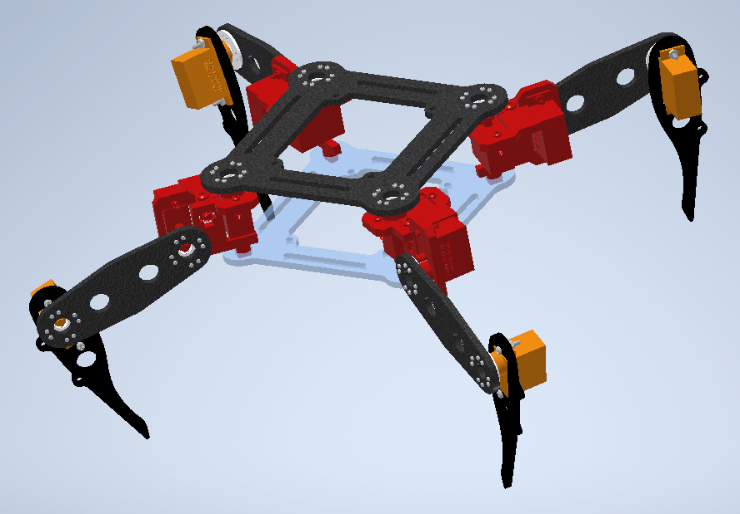

This robot package handler design has four legs, having three degrees of freedom in maneuverability each. The hip joint has two rotational points, which move the leg and limb together in the Z-axis direction. The knee joint only displaces the leg. The spheres illustrate the rotational maneuvers for the limb joint and the positions of dual servos. The joint connecting the limb and leg together also has a servo. Figure 1 is a 3D model of the robot. Figure 2 is a bottom view of the same model. The structure of the robot contains twelve rotating freedom points. The frame holds four limbs at each corner. The controller module, along with the servomechanism connectors and a battery pack, can be attached inside the body of the frame. A Wi-Fi module can be attached to the top of the controller module and secured to the frame. The claw consists of one degree of freedom, with four links and two gripper arms. Its operated with a servo and gears.

Modeling

Figure 1 Figure 2

Analysis Methods and Tools

For this project we will be implementing several methods to assist in solving our objectives. These methods include:

Implement (DFMA) Design for Manufacturing and Assembly methodology, which saves on the expense to manufacture and assemble our product.

Implement (DFQ) Design for Quality methodology which helps form a better product and process for our robot package handler’s development.

Implement (DFC) Design for Cost and (DFR) Design for Reliability which evaluates and analyzes lifecycle costs and that our product performs in the given environment a specific duty for our products expected life cycle.

CAD Software

Position Analysis

Acceleration Analysis

Mobility Analysis

Velocity Analysis

Force Analysis

Degrees of Freedom

Mechanism Design

Grabber Assembly Robot Assembly

Software Interface

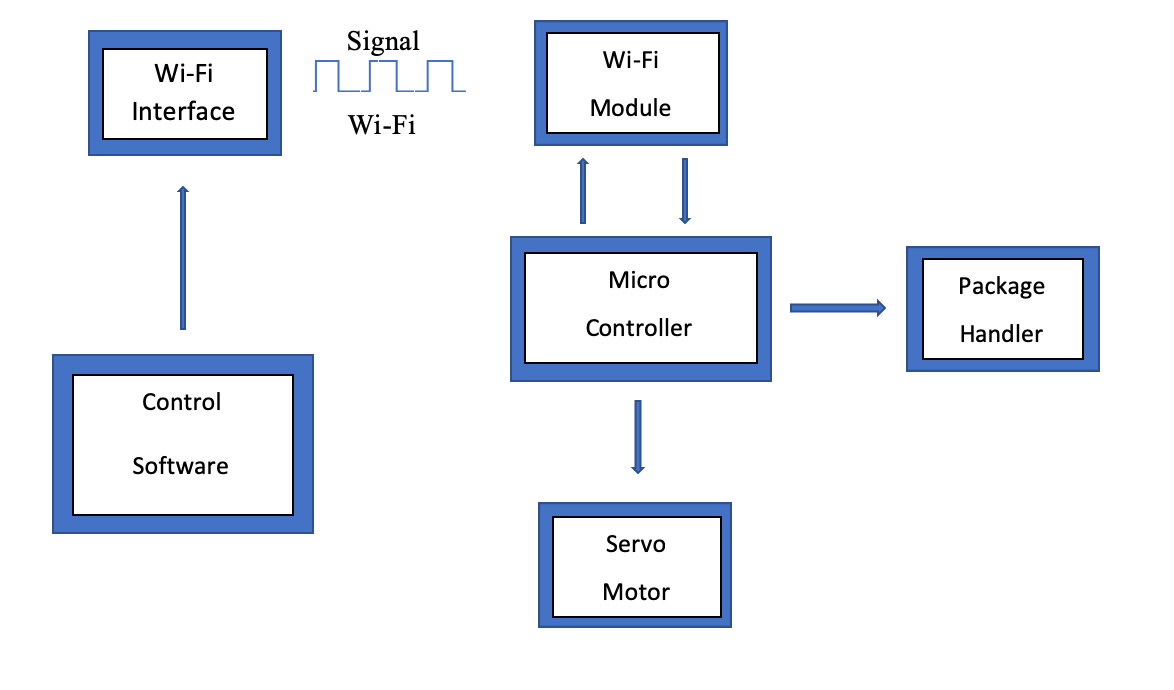

The robot handler is controlled using custom-made software. In the software design, the operator will turn on and off the control interface using the activate (Z) and deactivate (C). A diagram of the software interface is given in Figure 3. The control software will allow eight different maneuvers for the robot package handler including: raise up, lower down, forward walk, backward walk, left side walk, right side walk, 360-degree rotation in the right and left direction. They will be carried out by manipulating the forward (W), backwards (S), left turn (A), right turn (D), z-move, and z-rotate buttons. The velocity can also be controlled by using the switch (X) button. The Wi-Fi Module can be controlled with the Arduino Mega 2560 to establish wireless connection. The Arduino Mega 2560 will control fourteen servos.

Schematic 1

Robot Handler Walk Sequence

The walk sequence for movement for the robot handler has four directional movements (front, back, left, and right). The rotation in the clockwise and counterclockwise movements follow a different pattern for the servos. Every maneuver follows six steps (1 to 6) in order, shown below. The limbs are numbered from A to D.

The robot package handler starts at the rest position and all four legs feet will be on the ground.

Leg A and leg C will be positioning upwards in the Z direction. The maneuvering of the other legs will move the abdomen in respect to the ground.

The hip joints of leg B and leg D will change position toward the forward-left movement, with their feet positioned on the ground. Leg A and leg C will be elevated, the abdomen will move in the forward-left direction.

The feet of leg A and leg C will contact the ground and leg B and leg D will lift with respect to the ground.

Same as step 3, maneuvering of the abdomen is dependent on leg A and leg C and the abdomen will shift in the forward-right movement.

When all feet touch the ground, the robot package handler can be stable and stand. The abdomen will displace twice during the procedure. Beginning in the forward-left movement and then in forward-right movement. With a combination of these maneuvers, the robot package handler will move forward after the lifting of both legs in steps 2 and 4, the robot package handler shifts forward and is balanced.

The robot package handler can only keep stable on a set of legs in the stop position. However, the entire kinematic walking process occurs in short period of time, allowing the abdomen to move forward an rebalance in the stop position consecutively. If the robot package handler stops any point, it will be stable on all four legs.

Materials (Image 3)

ABS plastic parts - (Image 3)

(2) - ABS controller plates

(4) - ABS limb joints

(4) - ABS leg joints

(8) - ABS servo plates

ABS plastic parts grabber assembly

(2) - ABS forward links

(2) - ABS rear gear links

(1) - ABS grabber plate

(2) - ABS grabber hands

Wire

Wire protector

(13) - Servos kits with servo discs – (Image 4) (Image 4)

(6) - M3 x 27 standoffs

![Write a professional project report presenting all details and results for their design. The report must include: 1. Cover page (project title and complete names of all team members). 2. A “Frame of R 7]()

(6) - M3 x 5 Standoff screw

(6) – M3 x 12 Screw

(10) – M3 x 8 Screw

(30) - M2 Nuts

(6) – M3 Nuts

(26) - M2 x 10 Screw

(4) – M2 x 7 Screw

(100) – M1.2 x7 Self-Tapping Screw

(3) – B1 Bolts

(1) – B1S Bolt

(7) – N1 Nuts

Arduino Mega 2560 Controller

ESP8266 Wi-Fi Module

(2) – 3.7 V rechargeable battery

(1) – 9v battery

USB Cable

Tool Kit

Assembly Procedure- Robot Body

1. Place servo disc on the ABS top plate labeled B1, rotate the disc to align screw holes.

2. Install the (6) M1.2 x 7 screws on the opposite side of the servo disc, do not over tighten.

3. Repeat this step for the other 3 hip locations.

4. Take the ABS limb joint, labeled L1, rotate the disc to align screw holes.

5. Install the (6) M1.2 x 7 screws on the opposite side of the servo disc, do not over tighten

6. Repeat this step for the other 3 limb locations, install 2 disc per limb.

7. Take the ABS leg joints, labeled L2, position the servo thru the hole with gear in up position.

8. Install (2) M2 x 10 screws with (2) M2 nuts. Securing the servo to the leg. Do not over tighten.

9. Repeat this step for the 3 remaining legs. 2 of the legs should be facing in the opposite position from the other two.

10. Take ABS servo plate labeled S1, position the servo motor with the gear in up position.

11. Install (2) M2 x 7 screws with (2) M2 nuts, with plate notch outward. Do not over tighten.

12. Repeat this step for the 3 remaining plates. Two of them are opposite of the other two.

13. Take ABS servo plate labeled S2, position the servo with the gear in the down position.

14. Install (2) M2 x 10 screws with (2) M2 nuts, with plate notch down. Do not over tighten

15. Repeat this step for the 3 remaining plates. Two of them are opposite of the other two.

16. Take ABS servo plate S1, position it with gear facing up with screw hole toward ABS servo plate S2 with L notch toward S1. Place the nut in the bottom slot insert screw and tighten.

17. Do not over tighten.

18. Repeat this step for the 3 remaining plates. Two of them are opposite of the other two.

19. Install (4) M3 x 5 standoff screws through the 4 inner holes of the Arduino mega, to the (4) M3 x 27 standoffs spacers on the bottom side of the Arduino mega board. Do not over tighten.

20. Take ABS top plate labeled B1 Flip plate with screws facing up.

21. Install (4) M3 x 8 Screws through the middle 4 holes in the B1 plate to the (4) M3 x5 standoff screws. Do not over tighten.

22. Flip over the ABS top plate, make sure the switch is in the off position.

22. Install the (2) 3.7 V batteries in their slot.

23. Connect all servo plugs to the Arduino control board.

24. Install Logic to the Arduino control board.

25. Take the ABS top plate and the double assembled servo plates with gears facing up and gear facing away from the plate.

26. Install gear at 45-degree angle from the top plate.

27. Install (1) of the smallest screws from servo pack through the topside of servo disk to the top hole in the servo gear. Do not over tighten.

28. Repeat for the remainder double sided servo plates.

29. Take the ABS limb joint L1 and install the limb in horizontal position on the gear.

30. Install (1) of the smallest screws from the servo pack through the topside of the servo disk to the top hole in the servo gear. Do not over tighten.

31. Repeat for all remaining limb joints.

32. Take the ABS leg joint labeled L2 and install with the foot at a 90-degree position facing downward onto the gear of the servo.

33. Install (1) of the smallest screws from the servo pack through the topside of the servo disk to the top hole in the servo gear. Do not over tighten.

34. Repeat for all remaining leg joints.

35. Disconnect all the servo wires from the control board.

36. Using schematic (Figure 1) connect them in their spots as shown.

37. Take the ABS bottom plate labeled B2, place the plate over the spacers and align screw holes.

38. Install (4) M3 x 8 screws through the four holes opposite of the board, do not over tighten.

39. Clean up and arrange the servo wires so they do not obstruct the legs for their movement.

40. Wrap the wires with the wire protector cut to size.

41. Stand the robot handler on its feet and install the Wi-Fi module into its slot on the Arduino mega board controller.

42. Connect the robot using the usb cord from the Arduino to a computer.

43. Initiate the controller software.

44. Now start calibrating the robot.

45. Now we can test the robot.

46. Once we can fully control the robot, we are finished.

Assembly Procedure- Robot Grabber

1. Place servo on the ABS top plate labeled G1, adjust the servo to align screw holes.

2. Install the (2) M2 x 7 screws on the opposite side of the servo, install M2 nuts do not over tighten.

3. Place the black spacer on the hole to the side next to the servo, take gear arm labeled G1 and place it over the spacer, insert bolt B1 through the hole in G1 all the way through the plate and attach the nut labeled N1 and tighten to specification.

4. Take gear arm labeled G2 and place it over the servo bushing, insert bolt B1S through the hole in G2 all the way through the plate and tighten to specification.

5. Place the black spacer on the hole in front of the servo, take forward link arm labeled LK and place it over the spacer, insert bolt B1 through the hole in LK all the way through the plate and attach the nut labeled N1 and tighten to specification.

6. Place the black spacer on the hole to the front left of the servo, take forward link arm labeled LK and place it over the spacer, insert bolt B1 through the hole in LK all the way through the plate and attach the nut labeled N1 and tighten to specification.

7. Install grabber hand H1 on the links to the left of the servo, align holes and insert bolt B1 all the way through and attach nut labeled N1 and tighten to specification.

8. Install grabber hand H2 on the links attached to the servo, align holes, and insert bolt B1 all the way through and attach nut labeled N1 and tighten to specification.

9. Attach grabber hand assembly to the ABS top plate labeled B1 and center plate aligning markings, once aligned install the (2) M2 x 7 screws on the bottom side of ABS top plate and tighten to specification.

10. Clean up and arrange the servo wires so they do not obstruct the legs for their movement.

11. Wrap the wires with the wire protector cut to size.

12. Connect the robot using the usb cord from the Arduino to a computer.

13. Initiate the controller software.

14. Now start calibrating the robot grabber.

15. Now we can test the robot.

16. Once we can fully control the robot grabber, we are finished.

Discussion of the Design

The Robot Package Handler has both strengths and weaknesses. The handlers design strengths are that it is made from Aluminum with an ultimate tensile Strength of 45000 psi. The handler has four legs with 3 degrees of freedom with a hip joint that has two rotational points. This allows for the handlers walking motion so that It can maneuver around the factory that its stationed at. The handler’s controller module and the battery pack are all connected to the main body frame which is a sturdy connection point. Also, the handler’s controller module has a spot where a Wi-Fi module can be connected. The weaknesses of the handler’s design come from the handler can only keep stable on a set of legs in the stop position. So, user would have to ensure that all legs are on the ground unless the handler is moving to avoid a possible tip over. The handler will be made by default with Aluminum since it is more ductile, lighter, and cheaper. But if the purchaser wants, the handler can be made from carbon fiber. Carbon fiber offers stiffness and strength at a lower density than aluminum but is more expensive than aluminum. The handler requires $15.99 for the Arduino Mega 2560, $10.00 for the Arduinos Wi-Fi module, and $2500 for the aluminum or $3400 for the carbon fiber for the body, legs, and claw. The estimated total cost for the aluminum version is about $2600 and $3500 for the carbon fiber version. The potential customers will be any factories or freight companies worldwide that would like to advance to remote controlled freight handlers rather than the old-fashioned forklift. The handler’s direct competition are devices such as Automated Storage and Retrieval Systems (AS/RS), Goods-to-Person technology(G2P), Automated Guided vehicles and carts (AGV’s, AGC’s) and Articulated Robot Arms. AS/RS is used for heavier material and the function and is in the form of cranes to transport from shelves to ground level. G2P is for the delivery of the

product from factory to the buyer. Although very similar, the Robotic package handler has the edge due to being user controlled from the controller module.