Part 5 (total 1100 words):The distribution of our product from manufacturing site to store shelf(100words)· Develop a map that shows distribution route(s), DC locations, and transports mode

Running head: ADIDAS SHOES

Adidas Shoes

Student’s Name:

University Affiliation:

October 12, 2017

Part 5

The distribution of our product from manufacturing site to store shelf

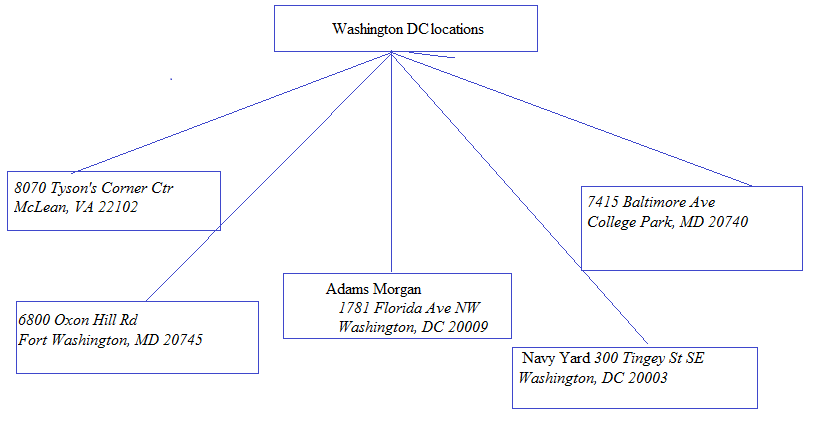

Develop a map that shows distribution route(s), DC locations, and transports modes used throughout.

Although Adidas is a growing and outspoken shoes company overseas, it has long struggled to establish and gain grounds in the United States and the rest of North America (Ahiza Garcia, 2017). To establish their market and get closer to the top, Adidas is focusing on establishing numerous shopping stores in major cities in the US such as Washington DC. They are also focusing on signing big-name athletes to authorization contracts, listening to their consumers and getting shoes into stores faster and thru the use of technology to introduce new designs and styles in the market. The need to reach a broad base of consumers in the US has made Adidas introduce new transport modes to accelerate the rate at which customers across different locations in Washington DC can gain possession of their goods.

The major distribution routes marked by the shoe stores for Adidas in Washington DC are;

8070 Tyson's Corner Ctr

McLean, VA 221026800 Oxon Hill Rd

Fort Washington, MD 20745Adams Morgan

1781 Florida Ave NW

Washington, DC 20009

Navy Yard

300 Tingey St SE

Washington, DC 20003

7415 Baltimore Ave

College Park, MD 20740

The distributions route is as shown in the map below;

Figure 1 Map showing distribution route(s), DC locations

Transportation involves different activities in the chain of the commodity like the transportation of goods or shoe products to the warehouses and transportation to the customers. The selection of different transit used is wholly based on the distance between the distribution center and the final destinations, costs and time have taken to deliver products within the DC areas. While Adidas opts for freights as the main shipping method overseas due to climatic change, deliveries within the DC locations is entire thru scheduled vehicle transportation based on delivery time and the cost incurred.

What is the estimated time for delivery?

The delivery time for the shoe products within DC location will vary depending on different factors such as the customer's preferred methods of delivery and locations. Often, item leaves the shipping warehouses in 2 business days after which they arrive at their designated locations in about 5-10 business days since the time they were shipped. In this case, the delivery time is a factor which is calculated by the addition of the warehouse handling time and shipping time.

Warehouse handling time has the likelihood of affecting the overall delivery time. The time taken for the product to reach to the customer will depend on the mode of transportation and the nature of products being delivered. Heavy products might take time to assemble and send to the consumers or the warehouse stores within DC location. Light and rather small goods will take less handling time which accelerates the rate at which they are speculated to reach their destination. The orders are also tracked to maintain the delivery time and ensure that they reach their customers on time.

A secure courier service is used to ensure that the delivery of the product reaches its destination in the right time to avoid major delays. Most of the locations within Washington DC such as

7415 Baltimore Ave

College Park, MD 20740, are easily reached due to their proximity to the main shopping stores. As a result, delivery time from the main warehouse to the customers located in this area could even record a delivery time of 48hrs or 72hrs excluding the weekends. Customers can also keep track of their products thru email and the tracking number. This keeps the customers updated about their products and any possible inquiry they might want to make regarding their product delivery. The average estimated delivery time remains 5-10 business days

Will we use your own transport fleet or contract 3PLs?

I will consider the 3PLs. Due to the increased dynamics of getting goods in the market, the Third-Party Logistics providers (3PLs) has grown vastly as the markets evolve. Traditionally, entry to the market involved making a noteworthy investment in facilities as well as infrastructure to guarantee the effectiveness of product delivery to the market. However, this practice has, as a result, changed since the Third-Party Logistics providers (3PLs) has the capability of dealing with all steps involved for the person ordering products from the company. This is efficient since it liberates the organization’s time as well as resources on vending the products.

Currently, the Third-Party Logistics providers (3PLs) can offer a wide variety of services compared to what they used to offer in recent years. This was because their main aim was on shipping and warehousing; when customers sent them their products, they simply sored and shipped it on their behalf. However, due to increased dynamics of the market today, the 3PLs can manage the entire Adidas enterprise inclusive of all the services offered such as delivery to the customers; it also comprises and support supply chain cycle, ordering management, e-commerce and information technology integration.

The major reasons for choosing 3PLs over transport fleet include;

Efficiency. The 3PLs guarantees both expertise and efficiency. This is ensured thru their use of technology and infrastructure to enhance their reputation to their customers who are located in different locations in the DC and around the world. The use of 3PLs also plays a great role in the Adidas shoe company development through reducing the costs and improving the services offered; this makes them ideal for use.

Technology. They have the latest technology which gives an individual benefit without having to make a capital investment. The increased use and growth of technology is among the increased benefits of opting to use the 3PLs.

Will we be using Private or Contract Warehouses?

I would sign a 3PLs with Contract Warehouses. Contract warehouses provide more specialized services which are not necessarily provided by other warehouses such as the public. Although they may lack the flexibility that is mostly given in public warehouses, they offer a guarantee. Considering a growing business-like Adidas, a contract warehousing would be considered to guarantee the safety of the products for the consumers across the country. Also, due to the daily growth of the shoe business, this type of warehousing would be considered since the warehousing setups are longtime based taking 3-5years (Liu, & Wang, 2009). In most cases, contract warehouses require their customers to dedicate themselves to a fixed period like mostly yearly for them to obtain the services. Also, they might not necessarily need their customers to hire or subsidize storage and material-handling facilities. The lower prices for contract warehouses is another consideration. Usually, their prices are lower per units of the items compared to other warehouses.

Also, they have the capacity of allowing for normal business expansion or contraction efficiently and flexible. Adidas Shoe company requiring to store their product in warehouses for an extended period would opt to use the contracted warehouse. The company will hence be able to store their products in a single facility without having to care about those products. They would later be at the position to distribute them to different destinations and shopping stores within DC locations. The process is somewhat flexible and productive for an increasingly growing company in the Western nations such as the United States and other locations such as North America.

Reference

Liu, H. T., & Wang, W. K. (2009). An integrated fuzzy approach for provider evaluation and selection in third-party logistics. Expert Systems with Applications, 36(3), 4387-4398.

Ahiza Garcia (2017). How Adidas is trying to catch Nike in the footwear race. Retrieved from http://money.cnn.com/2017/04/28/news/companies/mark-king-adidas-nike-under-armour/index.html

Fair Labor Association. (2009). Tracking Report 2009 Adidas Group, Vietnam 530284144H.

Dave Piasecki (2012). Public Warehouses, Contract Warehouses, and 3PLs Explained. Retrieved fromhttp://www.inventoryops.com/articles/public_warehouse_3pl.htm